After much reading and consideration I decided to go with the Holley 302-3 oil pan. While I was awaiting for the new, new oil pan to arrive I pulled the sending unit out of the new (1994) Caprice gas tank.

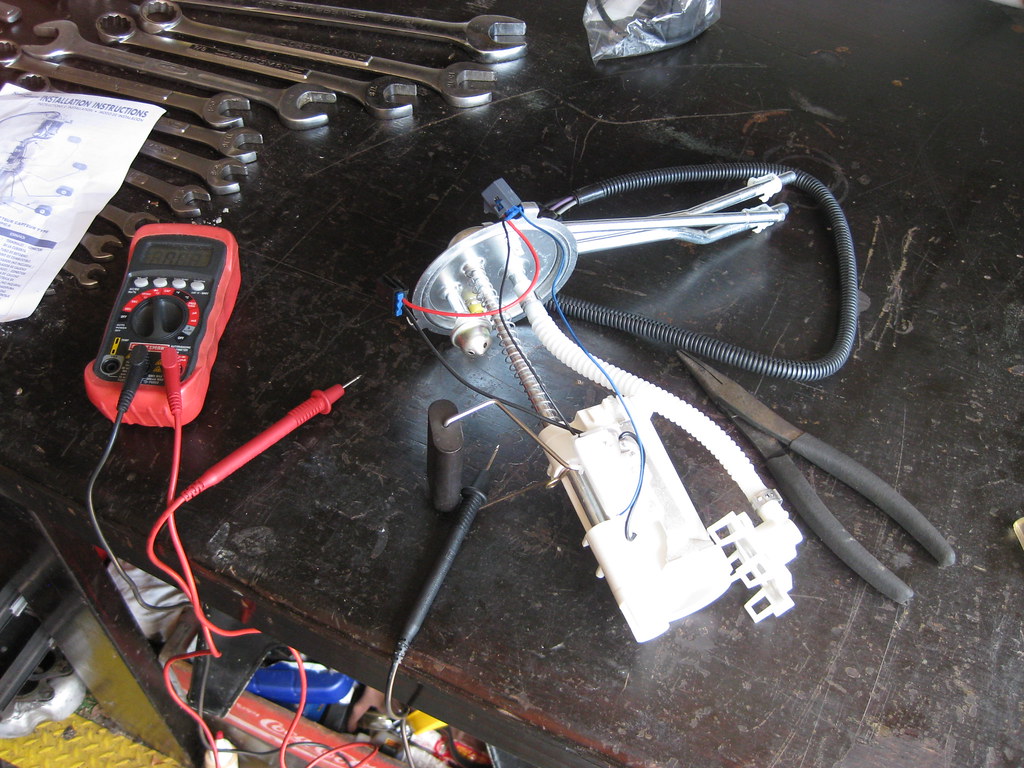

The picture below shows the reason this gas tank is used. The baffles shown hold the gasoline so when the fuel is low it does not slosh away from the pump. I cleaned away all of the debris.

Then I tested the new Delphi sending unit assembly to make sure it was registering 0-90 ohms between empty and full.

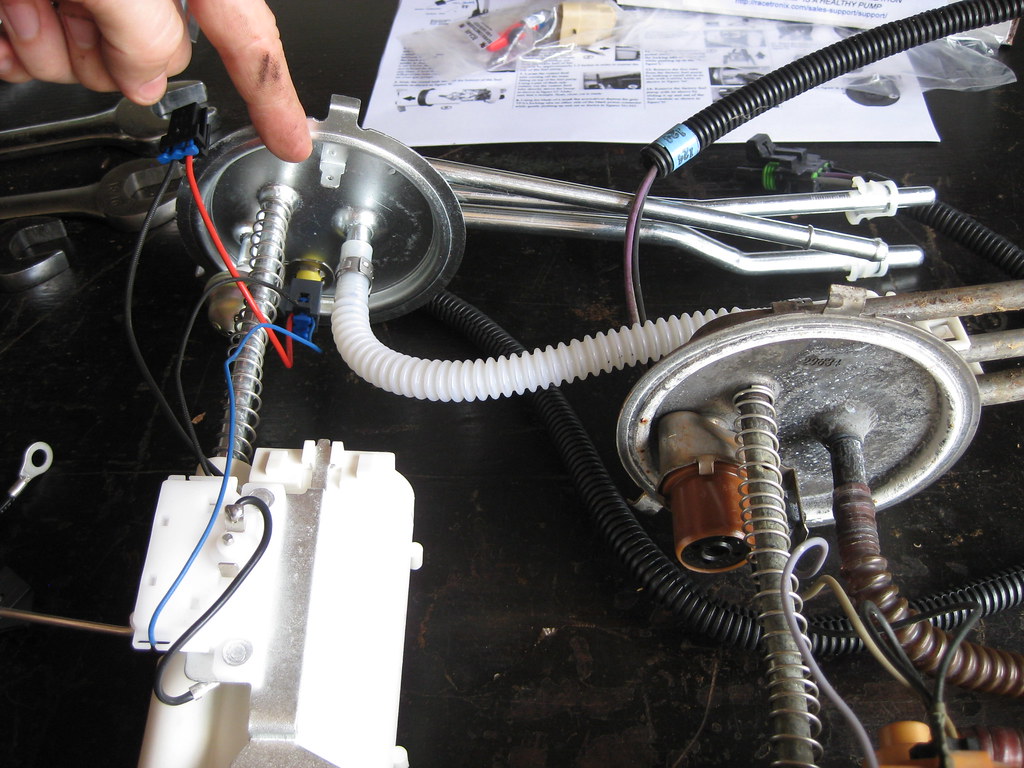

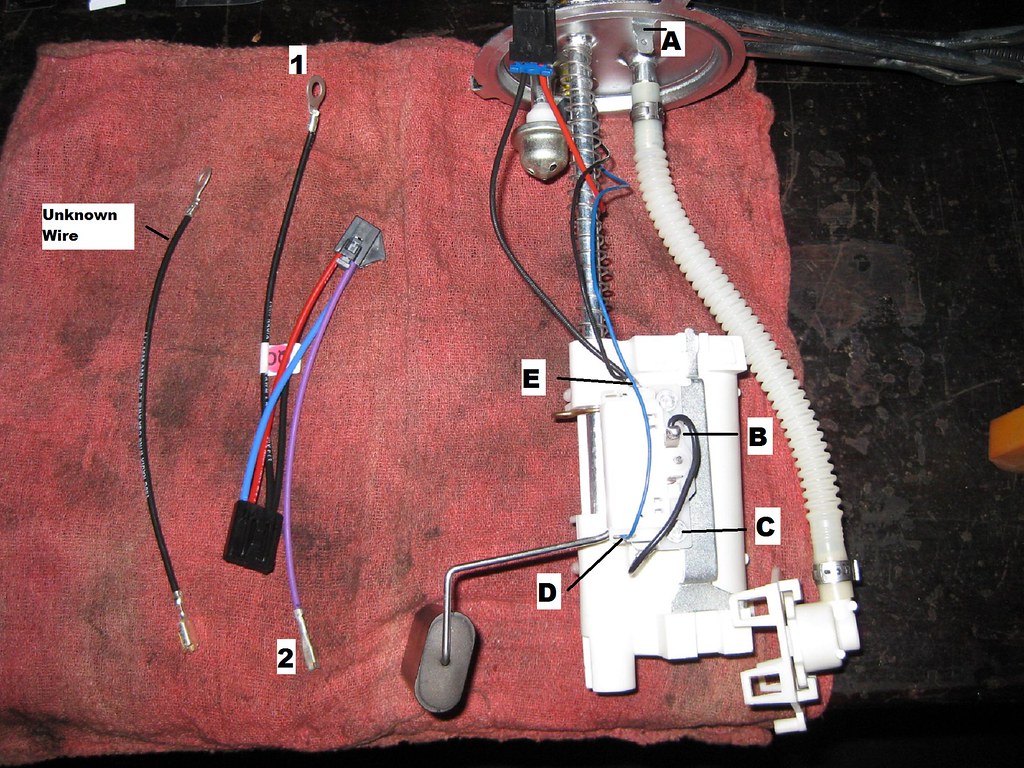

There were several differences between the original unit and the new unit. One was the way the wires hooked to the sender. Another was the addition of a blade connector hanging down from the lid of the sending unit assembly.

The wires on the new sending unit assembly were soldered and riveted to the sender. This mean you could not disconnect the wires and reconnect the wires from the new harness. Also, the manufacturer has changed their harness so the fittings and connectors are not the same as they used to be and past explanations on how to adapt this harness are no longer relevant. This company does not send instructions with their products. They require you to register for an internet forum which then must meet a moderators approval. As a result, I did not have access to the instructions the first day I tried to install these items. After receiving approval to the forum I found that the tech seemed unaware of the changes to the harness. I took the picture below and labeled all of the items with inquiries, however was still unable to get an answer to solve the problem. With help from a few other people online, I believe I have finally figured out how the new harness should be modified to fit on the sending unit assembly, but as of now I am not 100% sure.

The new Holley oil pan arrived that week and on Saturday my Father-In-Law was in town and helped me pull the engine out once again.

The Holley pan requires the use of an F-Body windage tray or a modified truck windage tray. Since I plan to use the F-Body oil pan that I'm now not going to be using on The Caprice for my '37 Chevrolet project and I won't have any future use for the old truck oil pan I decided to use the windage tray from the truck pan and modify it as described in the Holley's instructions. When I originally modified the pan below I cut it too long because I was using the portion of the directions which showed a close-up shot of the tray. I had to go back and recreate the cuts shown below at the next set of bolt holes on the tray.

I had some business on Saturday and when I got back my Father-in-Law and Father had the F-Body oil pan removed.

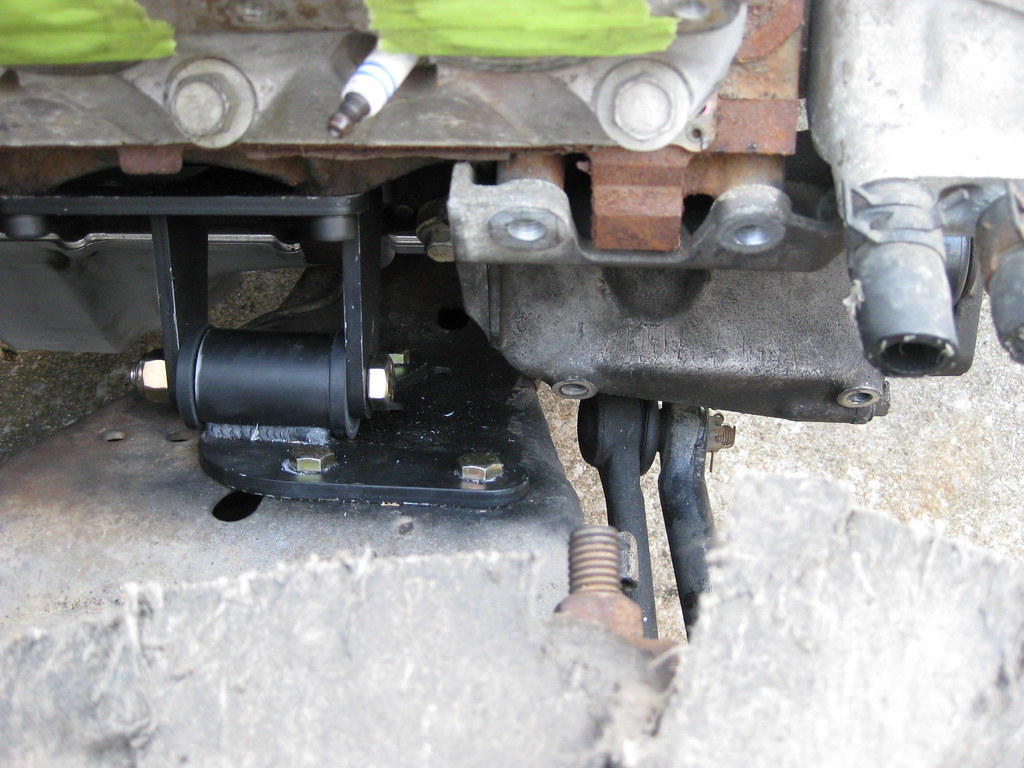

We installed the modified windage tray, pickup tube and Holley oil pan and then installed the engine.

The new pan fit great! It has somewhere around 1 3/4" between the sump area on the pan and the crossmember. What a relief. Unfortunately, the compressor on the lower passenger side will not fit. This BRP kit has been an utter disappointment. First the frame mounts did not fit and required modification. Then the instructions were abysmally insufficient causing me to have to communicate with the company several times. I will say the company was good to respond to my communications. Then the transmission mount, which was not supposed to require any drilling, turns out to require some very difficult to locate holes to be drilled in the frame. Then the bolts for the transmission mount aren't long enough, or they sent too many shims, I'm not sure which yet. I have contacted the company again to try to find out. The engine was very difficult to align and took the three of us several hours to get bolted into place.

This is how much room I have between the firewall and the back of the engine. I know some guys like to push their engine back as far as possible, but I'm more concerned with having sufficient room to reach the back of the engine for maintenance.

The photo below shows the compressor mount on the passenger side contacting the frame. The compressor obviously will not bolt in place and I am currently assessing my options on what to do about this situation. If I could move the entire engine forward 1 1/2" I believe the compressor would clear, but the oil pan would be very close. I test fit the new radiator to make sure I had enough room up front to play with. Other options involve cutting the frame to make room for the compressor or relocating the compressor. I believe the engine mount location will make notching the frame a non-option.