Due to the Thanksgiving holiday weekend, having Thanksgiving dinner at our house, being sick and a rainstorm, progress on the patch panel has been slow. It was unusually warm today and I had to go outside to try to make the best of it.

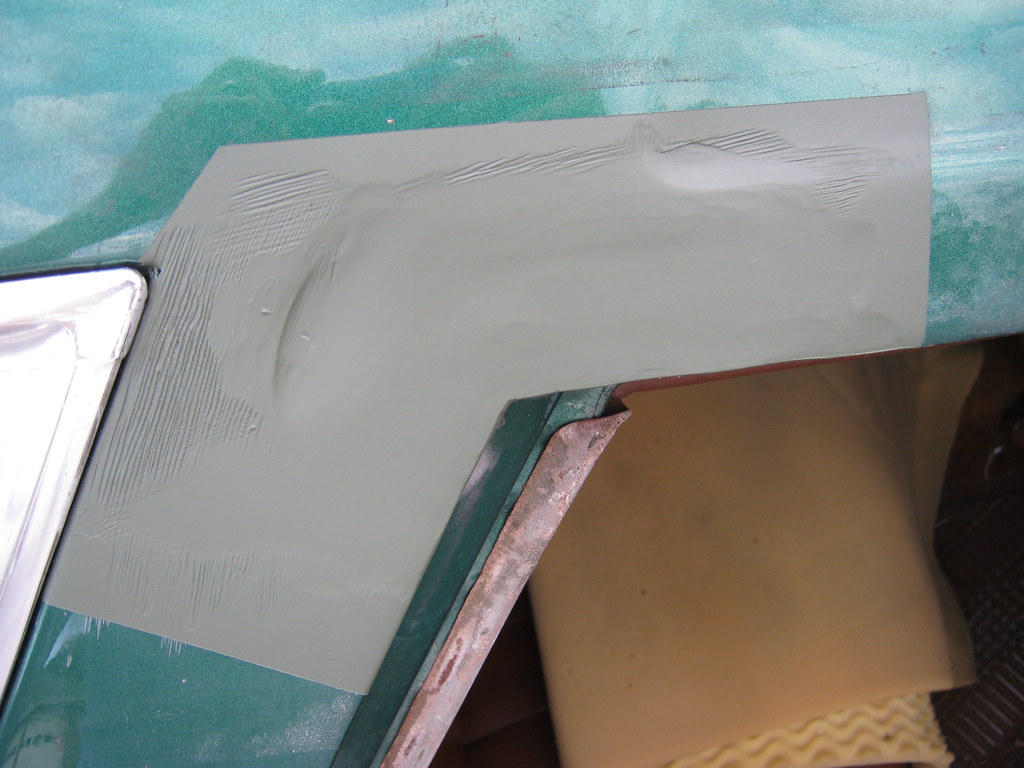

After a lot of welding, grinding and shaping the panel finally began to resemble a window corner. One of the difficulties was the fact that I couldn't weld anywhere close to the lead or it would melt so I had to create a divot to be fixed later at the bodyshop. Originally lead was used to build the panel up be smooth and the height it should be. I welded the patch panel in and then had to grind away all of the lead down to the metal underneath. Then I had to fill the height difference between where my patch panel was and where the metal was underneath. Then I had to taper that metal down to the base metal. Then I had to grind the lead so that it also tapered down to the metal also. Since I couldn't get close to the lead with the welder, the only way to fix this area would be to re-lead the entire area, or leave as much lead as I can and fix the rest with body filler. This is why there is a divot on the left side of the patch. At the bottom I ground away all of the lead and built the area back up with weld. The bottom of the patch was very difficult because that was an area where two thin pieces of metal came together and had to be welded into one piece. All I had was a large angle grinder and getting it into the corner and under the lip proved to be a challenge. One day I hope to have a proper air compressor so that I can use smaller, pneumatic tools that will allow shaping and accessing areas like this much easier than a cumbersome angle grinder.

The areas with the scuffed marks are where I used the wire brush to remove the paint and primer and lead. This will be feathered later during the bodywork. For now I just want to get everything coated with primer and protected.

The pictures were making it look better than it was. I wanted to get a picture that represented how the panel actually turned out. I prefer to have panels that require almost no filler afterwards, but in this case it was almost impossible. Some of the uneven surface is the sharp transition of the old primer and paint, as well as the indented, L-shaped body line. Next will be the lower dogleg in front of the passenger rear wheel.

Tuesday, November 29, 2016

Tuesday, November 22, 2016

Get The Lead Out

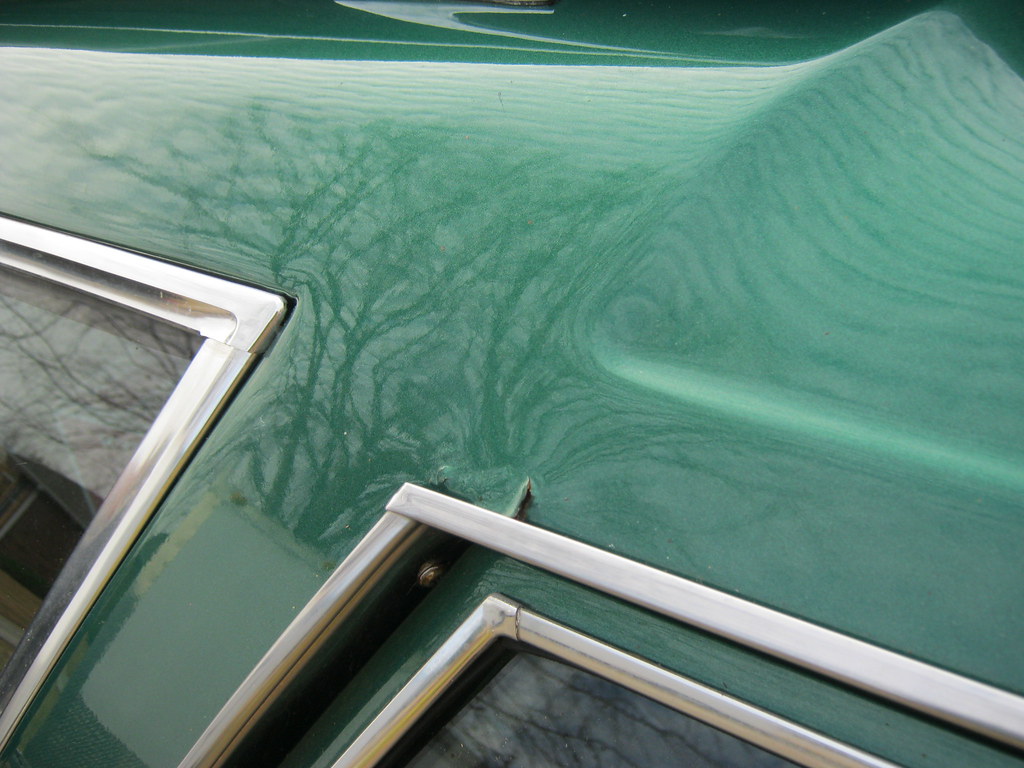

Today, it was time to tackle some rust issues. First up in the passenger side drip rail area. These cars are prone to issues in this area. Starting on this is a huge mental hurdle, but the only way it gets done is to jump in and do it. Here is the afflicted area.

The first step was removing the drip rail moldings.

After taping off the surrounding area for protection I cut open the tin can.

Here's the rust on the inner structure that caused the problem

Here's a wide shot of the area

I used a couple different wire brushs on the drill to clean the area thorougly

Then I covered everything with weld-through primer, making sure to coat everything I could reach inside the roof area. I let it dry while I went to lunch and when I came back I coated everything with the paraffin wax rust preventer.

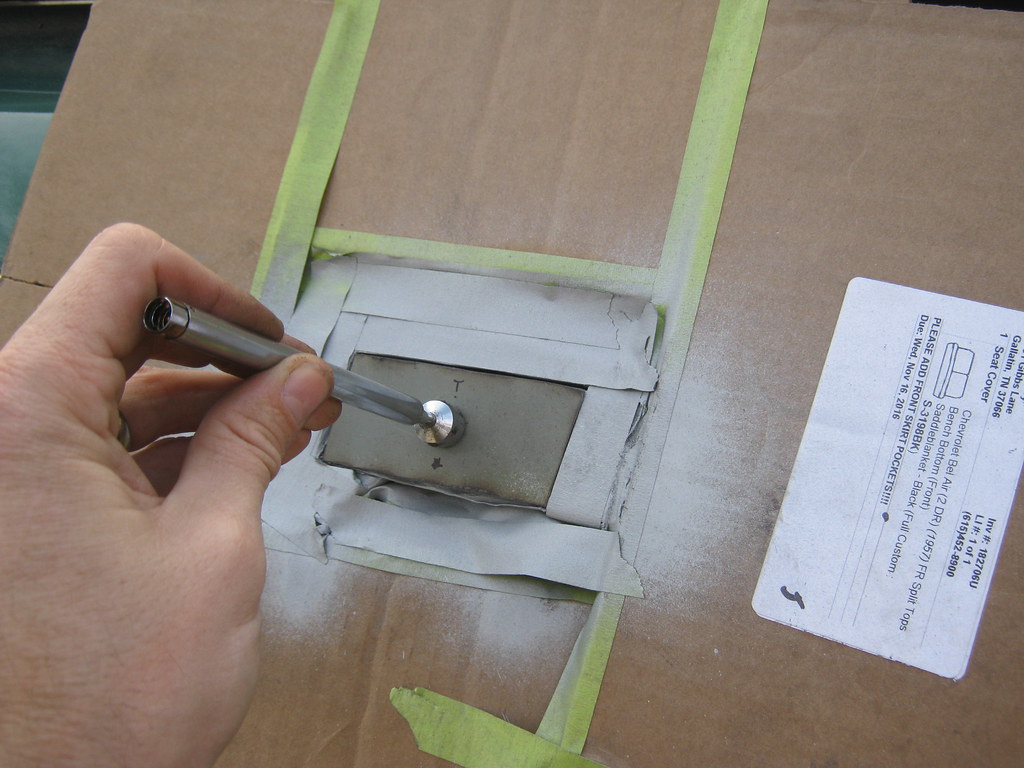

I used the old piece to make a template and cut out a new piece.

Test fitting the new patch

After I welded the top I rolled the bottom lip so I could weld it as well.

To weld the bottom it was necessary to open the door, which means I had to make sure I protected the original seats and door panels.

I ran into a problem on the left side. When I attempted to weld the metal on the car would instantly melt away like butter and made a very different sound than it normally does. The problem was that this area was full of lead. This was the area the factory attached two panels together and they used lead as body filler to smooth the transition.

I used the wire brush to remove the paint and primer and see what areas were coated with lead. You can see lead here as the area with scratches. Lead is soft and the wire brush scored the area.

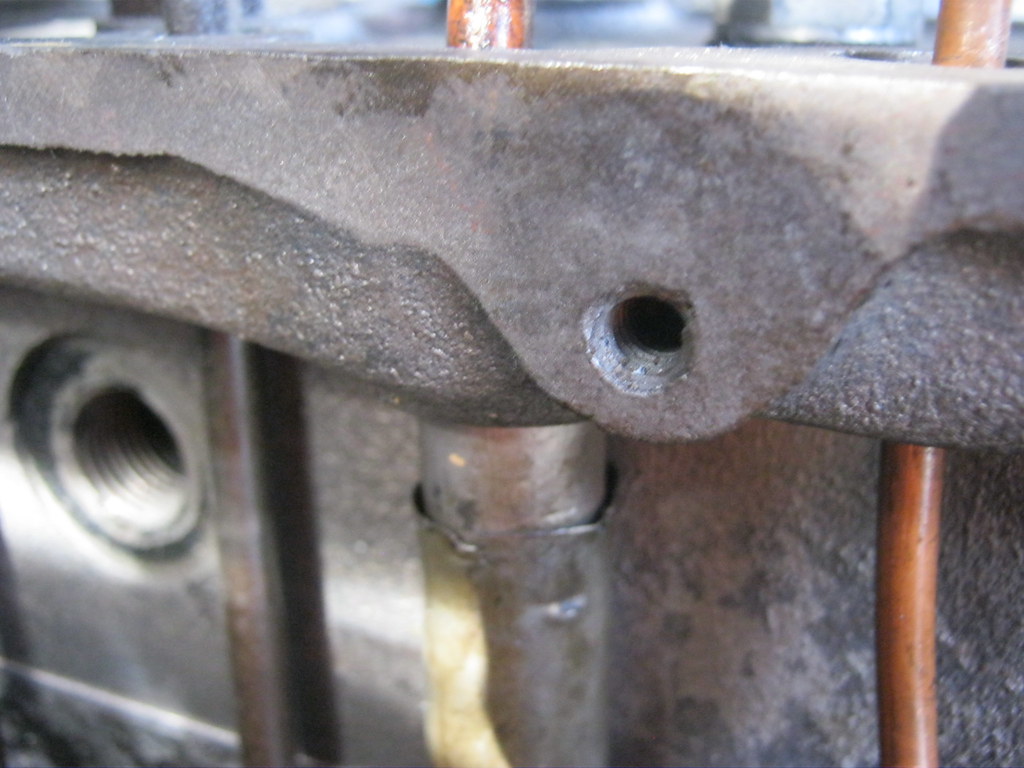

The angle of this picture unfortunately doesn't show the depth, but I used a grinder to grind away the lead down to bare metal which gave me something to weld to. The actual metal was about 1/8th inch deep so I had to slowly build up weld material to the right height to connect the patch panel. Then I put the end of the spray tube into the holes at the bottom and filled the cavity with the paraffin wax rust protector.

I covered everything with primer to protect it until I'm able to get back to it.

The first step was removing the drip rail moldings.

After taping off the surrounding area for protection I cut open the tin can.

Here's the rust on the inner structure that caused the problem

Here's a wide shot of the area

I used a couple different wire brushs on the drill to clean the area thorougly

Then I covered everything with weld-through primer, making sure to coat everything I could reach inside the roof area. I let it dry while I went to lunch and when I came back I coated everything with the paraffin wax rust preventer.

I used the old piece to make a template and cut out a new piece.

Test fitting the new patch

After I welded the top I rolled the bottom lip so I could weld it as well.

To weld the bottom it was necessary to open the door, which means I had to make sure I protected the original seats and door panels.

I ran into a problem on the left side. When I attempted to weld the metal on the car would instantly melt away like butter and made a very different sound than it normally does. The problem was that this area was full of lead. This was the area the factory attached two panels together and they used lead as body filler to smooth the transition.

I used the wire brush to remove the paint and primer and see what areas were coated with lead. You can see lead here as the area with scratches. Lead is soft and the wire brush scored the area.

The angle of this picture unfortunately doesn't show the depth, but I used a grinder to grind away the lead down to bare metal which gave me something to weld to. The actual metal was about 1/8th inch deep so I had to slowly build up weld material to the right height to connect the patch panel. Then I put the end of the spray tube into the holes at the bottom and filled the cavity with the paraffin wax rust protector.

I covered everything with primer to protect it until I'm able to get back to it.

Monday, November 21, 2016

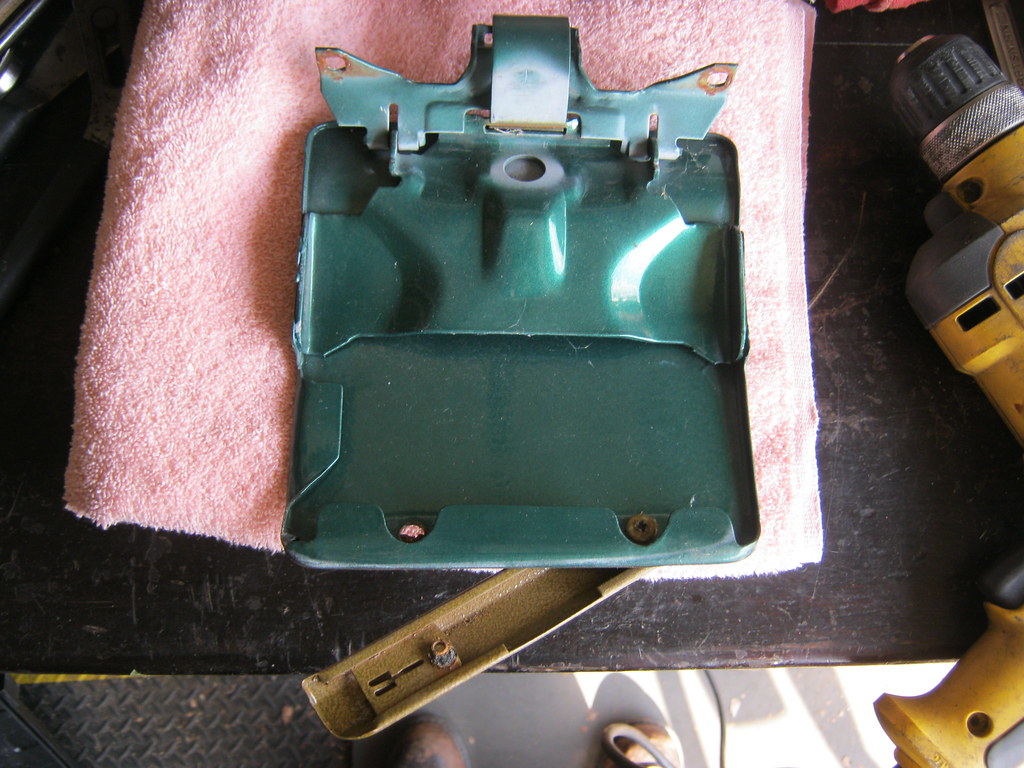

Little Green Grand Ville Hood

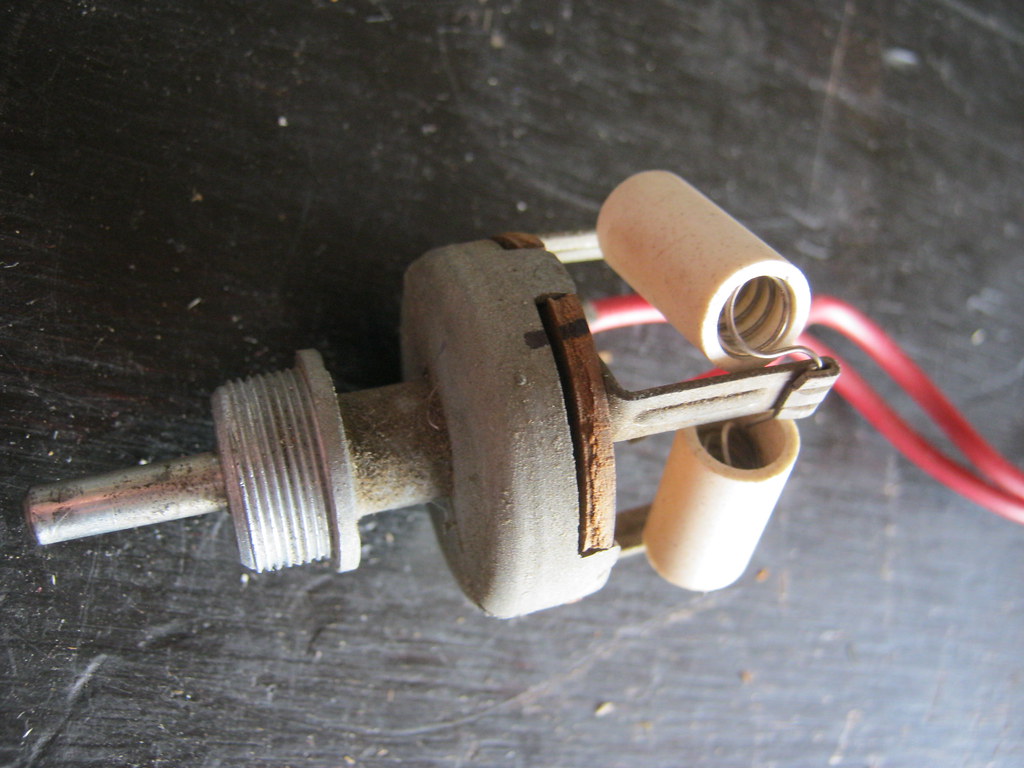

The heater in the '57 has never worked exactly right. This car has the cheapest model heater, which is the non-deluxe option, called a recirculating heater. This heater only has two buttons, one that you pull to direct the air to the floor or to the defroster vents and the other is a rheostat that turns the heater from off to high, medium or low. It is called a recirculating heater because unlike the deluxe heater, this heater only recirculates air from inside the cabin. It lacks any ability to blend incoming air, however the car does have two vents in the firewall that take in air directly from above the headlights, so even though the heater has no blend provision, technically you can blend the outside vents in combination with the heater vent to get an acceptable amount of hot and cold air into the cabin. With the recirculating heater, if there is no passenger in the car you cannot safely reach the vent knob on the passenger side of the car. The deluxe controls have the vent opening knobs together where my two control knobs are.

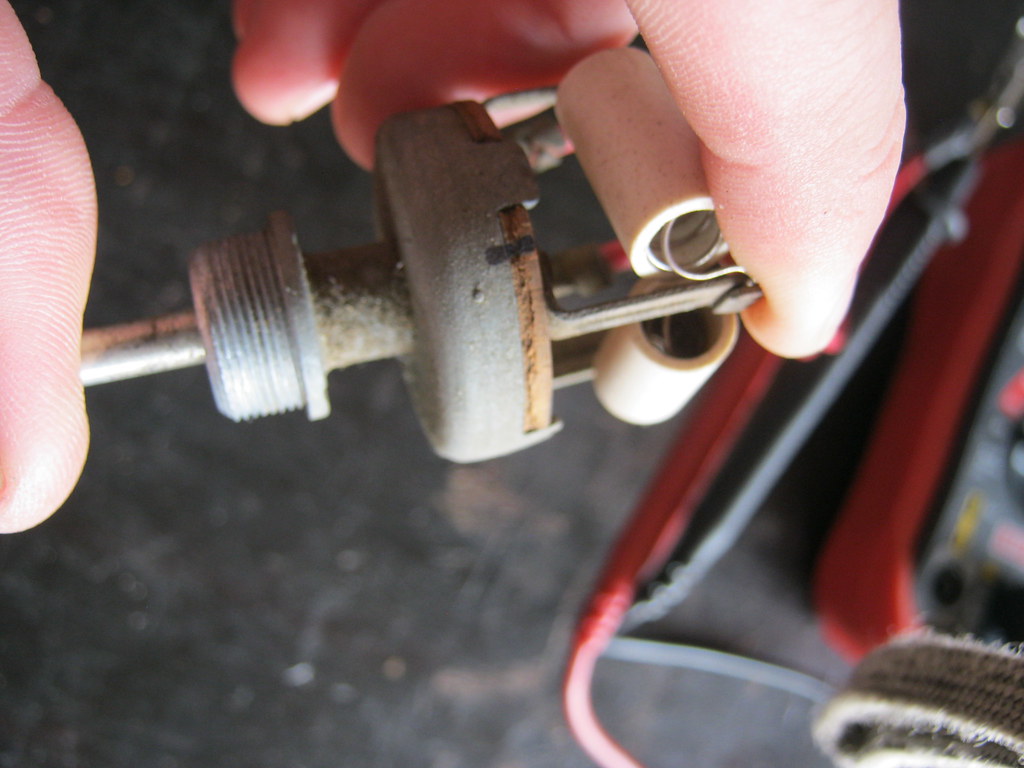

In the past the fan control has only worked on high and sometimes on low, if you played with the button just right, and then sometimes it would turn off and when it was on low it was so quiet you couldn't tell that it was off unless you held your hand under the vent or began to get cold. I took the switch out expecting it to be bad or in need of cleaning. I noticed that the cardboard backing plate was not tight against the body of the switch because the tabs that are bent to hold it in place were loose.

I bent the tabs tighter and tested the ohms of the switch with the multimeter and found that the problem was fixed. It was about the easiest fix I've ever had. The only issue I had was that one day on the way back home from town the switch stuck on high and wouldn't turn off. I took the switch back out, adjusted it and it's been working good since.

April drove the Suburban on about a 300 mile trip. Right after she got back the check engine light came on. I ran by the local parts house and had them read the code from the computer and it showed a P0161, which is a bank 2 sensor 2 code. This means that the oxygen sensor on the passenger side, behind the catalytic converter had a heater element that was bad. Oxygen sensors must maintain a certain temperature to operate correctly. In order to get them to work before the engine heats up to operating temperature each of the four oxygen sensors has its own heater element. After looking online quite a bit to determine the best way to diagnose the issue, I tested the wiring harness. I had suspected that since I had just disconnected so many wires when I replaced the intake manifold gaskets that a wire connector was probably bad or a wire had rubbed through and was shorting out. It turned out to just be a coincidence and was unrelated to the previous work I had done. The heater element inside the sensor itself had gone bad. I ordered another sensor, rented a removal tool from the parts store, installed the new sensor and everything was back to good.

Upholstery shops wanted about $1,500 to install new, factory appearing seat covers for the '57. This wasn't even in the realm of possibilty so for Christmas Mother and Father, at my request, got me a saddle blanket seat cover for The '57. A 50/50 split-back bench seat has apparently become somewhat uncommon and had to be custom ordered. Mom and dad let me have it early because riding around on the towels and decaying eggshell mattress foam was very annoying, not to mention that installing the seat cover, which is time consuming, is much better in 60 degree weather than 20 or 30 degree weather. I had installed one of these years ago and enjoyed it for the first few days. I didn't realize that what I had bought was a very cheap brand and within about three months it began to rot and decay. It turned into a very fine granular material that began to come apart in your hands and blow in your eyes when you rode in the car with the windows down or vents open. Not only that, it turned into a very itchy substance that would not easily come off your skin even if you simply laid your hand down on the seat.

As you can see, the old seat is pretty much unusable. The brown seat material is like steel wool and if you try to sit on it, it will poke through your pants and into your leg. Also, the old padding wads up and falls apart and gets everywhere. Mice absolutely love this stuff. Every time I park the car for over a month I found about a square foot of this stuff in my trunk.

I bought a new sheet of eggshell mattress foam to help cushion the seat since so much of it had rotted away. I measured and cut it into three pieces and then trimmed the pieces to fit.

It took a while, but I like the end result. The process is kind of a pain, but getting the screws to line back up in the side and bottom panels was the worst part. The company sewed pockets into the front which is very, very useful since I don't really have anywhere to store my registration, remote for the radio or sunglasses. The color and design go very well with the original design of the door panels and rear seats.

After a lot, and I mean several days, of scrubbing and cleaning I finally removed almost all of the old woodgrain. My fingers were literally bruised and numb. I have yet to remove the woodgrain on the tailgate because I'm going to have to hook a car battery to the motors to let the window up and tailgate down, which is necessary to remove the woodgrain trim pieces on the left and right of the tailgate. One of the screws for the woodgrain trim on the gas door would not come all of the way out and I ended up having to drill it out.

I took Adam, the body and paint guy, the hood. Let me be clear. Not the first hood that was wrecked, or the second hood that I bought on the parts clip, but the third hood. The one I had to buy after Adam saw the other one and said it was so bad it wasn't worth fixing. Adam said all the panels on the parts-clip hood were wavy and would cost a fortune to get straight, and even then there was no guarantee it would stay straight after all the materials shrank and flexed. I had to find another hood. I remembered that somewhere around a year ago I had talked to a guy about two hours from Nashville that had a huge stash of demo derby cars and in those cars was a 1971 Pontiac Wagon. He wouldn't sell the car as a whole and at the time I was looking for a full parts car. Also, the front passenger fender was dented, which was a big part of why I needed a parts car. He had sent me pictures of it. I spent forever combing my old and deleted emails and forums posts but couldn't come up with anything in the way of correspondence I had with the guy. In desperation I posted to all of the appropriate places on the internet a very general description of the guy I had talked to: Two hours from Nashville, lots of demolition derby cars, 71 Pontiac wagon. Eventually, someone on a demolition derby forum posted the name of a guy that could be the man I was looking for. I contacted him and sure enough, it was the same guy. He checked the hood and called me back and said it was straight and would be suitable to use. That next Saturday I borrowed Dad's truck and small trailer and we headed down South.

When we first pulled up to the place, in the middle of nowhere, there was a shop surrounded by some older cars. As we got out a little kid about 3 years old, with a Batman jacket, came out of the door of the shop, snot running down his nose, and ran by me and ran up to dad and gave him a big hug like they'd known each other for years. We walked in the shop and there was a guy working on restoring a 1971 Kingswood clamshell. He looked really familiar but I couldn't place it. Dad and I talked to him and I was looking at one of his cars while he was talking to dad and suddenly his voice hit me. It turned out that this guy was Tommy from the TV show Muscle Cars, which is now called Detroit Muscle. It was so unexpected that even after I was pretty sure it was him I was afraid to ask because it seemed so random and unlikely. After talking a while, Tommy showed us a couple of his project cars that had been on the show and we made our way back to where the '71 wagon was. Unfortunately, of all the times, I forgot to take my camera. To my surprise, it was actually a non-woodgrain Grand Safari rather than just a Safari. I'm very thankful to have found the car, but if ONLY it could have had the woodgrain trim. It did mean, however, that the grill would work with mine. The hood was in excellent shape and so was the grill and header panel. The driver side quarter extension was great, but the passenger side fender and quarter extension were dented beyond practical use. The bumper was also dented. They were damaged because Tommy had bought this car to demolition derby so when his friend that he bought it from loaded it he did so with a bulldozer, thus ruining the front parts I mentioned above. That was really, really unfortunate. I not only got the hood but I ended up getting the grill as well, and since the grill was bolted to the header panel I went ahead and got it to because when the sandblasters had stripped the previous header panel it had made the plastic somewhat orange-peeled in some areas. It was able to be repaired, but I thought just in case I better get another one while the getting was good. Tommy was also able to give me the contact information of a great airbrush artist that will be able to paint the woodgrain.

I loaded the new hood and took it to Adam. He gave his approval of the great condition of the new hood, which was a relief.

Since the parts-clip had a Safari grill instead of a Grand Safari grill, I was going to have to find a passenger side grill. Fortunately, this parts car had the right grill and it wasn't broken at all.

I also got a completely intact and unbroken fan shroud. I got the parking light lens and reflector for the passenger side and since the quarter extension was busted all to pieces Tommy just gave me the whole piece. The front emblem is also much nicer than the other two I have, so I'll use it when reinstalling everything.

When I dropped the hood at Adam's he said that the other pieces were primed and ready for paint.

It's hard to tell from the photos but Adam's shop is on top of a huge hill. The view is great but getting up there on the gravel road can be difficult. I have to borrow dad's 4x4 to be able to pull a trailer up it. The '57 won't make it without a good running start thanks to its narrow tires. It doesn't translate into photo but thew view from the top is amazing.

In the past the fan control has only worked on high and sometimes on low, if you played with the button just right, and then sometimes it would turn off and when it was on low it was so quiet you couldn't tell that it was off unless you held your hand under the vent or began to get cold. I took the switch out expecting it to be bad or in need of cleaning. I noticed that the cardboard backing plate was not tight against the body of the switch because the tabs that are bent to hold it in place were loose.

I bent the tabs tighter and tested the ohms of the switch with the multimeter and found that the problem was fixed. It was about the easiest fix I've ever had. The only issue I had was that one day on the way back home from town the switch stuck on high and wouldn't turn off. I took the switch back out, adjusted it and it's been working good since.

April drove the Suburban on about a 300 mile trip. Right after she got back the check engine light came on. I ran by the local parts house and had them read the code from the computer and it showed a P0161, which is a bank 2 sensor 2 code. This means that the oxygen sensor on the passenger side, behind the catalytic converter had a heater element that was bad. Oxygen sensors must maintain a certain temperature to operate correctly. In order to get them to work before the engine heats up to operating temperature each of the four oxygen sensors has its own heater element. After looking online quite a bit to determine the best way to diagnose the issue, I tested the wiring harness. I had suspected that since I had just disconnected so many wires when I replaced the intake manifold gaskets that a wire connector was probably bad or a wire had rubbed through and was shorting out. It turned out to just be a coincidence and was unrelated to the previous work I had done. The heater element inside the sensor itself had gone bad. I ordered another sensor, rented a removal tool from the parts store, installed the new sensor and everything was back to good.

Upholstery shops wanted about $1,500 to install new, factory appearing seat covers for the '57. This wasn't even in the realm of possibilty so for Christmas Mother and Father, at my request, got me a saddle blanket seat cover for The '57. A 50/50 split-back bench seat has apparently become somewhat uncommon and had to be custom ordered. Mom and dad let me have it early because riding around on the towels and decaying eggshell mattress foam was very annoying, not to mention that installing the seat cover, which is time consuming, is much better in 60 degree weather than 20 or 30 degree weather. I had installed one of these years ago and enjoyed it for the first few days. I didn't realize that what I had bought was a very cheap brand and within about three months it began to rot and decay. It turned into a very fine granular material that began to come apart in your hands and blow in your eyes when you rode in the car with the windows down or vents open. Not only that, it turned into a very itchy substance that would not easily come off your skin even if you simply laid your hand down on the seat.

As you can see, the old seat is pretty much unusable. The brown seat material is like steel wool and if you try to sit on it, it will poke through your pants and into your leg. Also, the old padding wads up and falls apart and gets everywhere. Mice absolutely love this stuff. Every time I park the car for over a month I found about a square foot of this stuff in my trunk.

I bought a new sheet of eggshell mattress foam to help cushion the seat since so much of it had rotted away. I measured and cut it into three pieces and then trimmed the pieces to fit.

It took a while, but I like the end result. The process is kind of a pain, but getting the screws to line back up in the side and bottom panels was the worst part. The company sewed pockets into the front which is very, very useful since I don't really have anywhere to store my registration, remote for the radio or sunglasses. The color and design go very well with the original design of the door panels and rear seats.

After a lot, and I mean several days, of scrubbing and cleaning I finally removed almost all of the old woodgrain. My fingers were literally bruised and numb. I have yet to remove the woodgrain on the tailgate because I'm going to have to hook a car battery to the motors to let the window up and tailgate down, which is necessary to remove the woodgrain trim pieces on the left and right of the tailgate. One of the screws for the woodgrain trim on the gas door would not come all of the way out and I ended up having to drill it out.

I took Adam, the body and paint guy, the hood. Let me be clear. Not the first hood that was wrecked, or the second hood that I bought on the parts clip, but the third hood. The one I had to buy after Adam saw the other one and said it was so bad it wasn't worth fixing. Adam said all the panels on the parts-clip hood were wavy and would cost a fortune to get straight, and even then there was no guarantee it would stay straight after all the materials shrank and flexed. I had to find another hood. I remembered that somewhere around a year ago I had talked to a guy about two hours from Nashville that had a huge stash of demo derby cars and in those cars was a 1971 Pontiac Wagon. He wouldn't sell the car as a whole and at the time I was looking for a full parts car. Also, the front passenger fender was dented, which was a big part of why I needed a parts car. He had sent me pictures of it. I spent forever combing my old and deleted emails and forums posts but couldn't come up with anything in the way of correspondence I had with the guy. In desperation I posted to all of the appropriate places on the internet a very general description of the guy I had talked to: Two hours from Nashville, lots of demolition derby cars, 71 Pontiac wagon. Eventually, someone on a demolition derby forum posted the name of a guy that could be the man I was looking for. I contacted him and sure enough, it was the same guy. He checked the hood and called me back and said it was straight and would be suitable to use. That next Saturday I borrowed Dad's truck and small trailer and we headed down South.

When we first pulled up to the place, in the middle of nowhere, there was a shop surrounded by some older cars. As we got out a little kid about 3 years old, with a Batman jacket, came out of the door of the shop, snot running down his nose, and ran by me and ran up to dad and gave him a big hug like they'd known each other for years. We walked in the shop and there was a guy working on restoring a 1971 Kingswood clamshell. He looked really familiar but I couldn't place it. Dad and I talked to him and I was looking at one of his cars while he was talking to dad and suddenly his voice hit me. It turned out that this guy was Tommy from the TV show Muscle Cars, which is now called Detroit Muscle. It was so unexpected that even after I was pretty sure it was him I was afraid to ask because it seemed so random and unlikely. After talking a while, Tommy showed us a couple of his project cars that had been on the show and we made our way back to where the '71 wagon was. Unfortunately, of all the times, I forgot to take my camera. To my surprise, it was actually a non-woodgrain Grand Safari rather than just a Safari. I'm very thankful to have found the car, but if ONLY it could have had the woodgrain trim. It did mean, however, that the grill would work with mine. The hood was in excellent shape and so was the grill and header panel. The driver side quarter extension was great, but the passenger side fender and quarter extension were dented beyond practical use. The bumper was also dented. They were damaged because Tommy had bought this car to demolition derby so when his friend that he bought it from loaded it he did so with a bulldozer, thus ruining the front parts I mentioned above. That was really, really unfortunate. I not only got the hood but I ended up getting the grill as well, and since the grill was bolted to the header panel I went ahead and got it to because when the sandblasters had stripped the previous header panel it had made the plastic somewhat orange-peeled in some areas. It was able to be repaired, but I thought just in case I better get another one while the getting was good. Tommy was also able to give me the contact information of a great airbrush artist that will be able to paint the woodgrain.

I loaded the new hood and took it to Adam. He gave his approval of the great condition of the new hood, which was a relief.

Since the parts-clip had a Safari grill instead of a Grand Safari grill, I was going to have to find a passenger side grill. Fortunately, this parts car had the right grill and it wasn't broken at all.

I also got a completely intact and unbroken fan shroud. I got the parking light lens and reflector for the passenger side and since the quarter extension was busted all to pieces Tommy just gave me the whole piece. The front emblem is also much nicer than the other two I have, so I'll use it when reinstalling everything.

When I dropped the hood at Adam's he said that the other pieces were primed and ready for paint.

It's hard to tell from the photos but Adam's shop is on top of a huge hill. The view is great but getting up there on the gravel road can be difficult. I have to borrow dad's 4x4 to be able to pull a trailer up it. The '57 won't make it without a good running start thanks to its narrow tires. It doesn't translate into photo but thew view from the top is amazing.

Wednesday, November 9, 2016

Tedious

When I dropped the parts off at the bodyshop, Adam, the guy that's going to do the work, said the hood was so bad he didn't really want to work with it. If you ran your hand flat against every panel you could feel waves in every surface. He said there would be more money in the hours it would take to fix it than it would ever be worth, and the stretched metal was so flimsy that you could never guarantee it would be straight, or stay straight once everything started shrinking. I put some feelers out on the internet to find a guy I had once contacted about some wagon parts. He had a '71 Safari, but didn't want to sell it as a whole car. Someone finally found him online and I called him. He's going to check the hood and if it looks solid I'll be going to look at it. The good thing is he's only about two hours away, possibly less.

I've been working on removing the woodgrain trim, woodgrain and the glue under it. It has been very time consuming and tedious. My fingers feel as though they're rubbed down to the bone.

Adhesive cleaner in a spray can and a shop rag.

The woodgrain peeled the clear coat off under the rear door handle. I don't suppose it will matter since this area will be stripped and repainted with faux-woodgrain.

If you own an old car, there's a high likely hood that you will acquire parts. If you work on old cars you will, without a doubt, begin to accrue old car parts. You won't necessarily make a conscious effort to do so, but they will eventually, over the years, just begin to follow you home and accumulate one way or another. Sometimes working on old cars doesn't just mean working on old cars, sometimes it means scrubbing glue off 15 miles worth of quarter panels. Sometimes it means climbing over cars and boats and huge spider webs to hoist heavy and cumbersome car parts in a barn loft for safe keeping. Try not to fall out of the barn loft.

I've been working on removing the woodgrain trim, woodgrain and the glue under it. It has been very time consuming and tedious. My fingers feel as though they're rubbed down to the bone.

Adhesive cleaner in a spray can and a shop rag.

The woodgrain peeled the clear coat off under the rear door handle. I don't suppose it will matter since this area will be stripped and repainted with faux-woodgrain.

If you own an old car, there's a high likely hood that you will acquire parts. If you work on old cars you will, without a doubt, begin to accrue old car parts. You won't necessarily make a conscious effort to do so, but they will eventually, over the years, just begin to follow you home and accumulate one way or another. Sometimes working on old cars doesn't just mean working on old cars, sometimes it means scrubbing glue off 15 miles worth of quarter panels. Sometimes it means climbing over cars and boats and huge spider webs to hoist heavy and cumbersome car parts in a barn loft for safe keeping. Try not to fall out of the barn loft.

Monday, November 7, 2016

Scattered, Smothered and Covered Up With Problems

The following list of projects took a couple of weeks and the time frames were overlapping or simultaneous.

With the sand dried out I was able to clean the area under the newly removed sheet metal. I got out the Speed Blaster, which I purchased when I was working on The Wagon the first time. It is time consuming and frustrating to use, but much better than nothing.

Here is the area after being sand blasted.

After sand blasting all of the braces I primered it and then came back with the paraffin wax rust coating.

Then I tack welded the new panel into place.

One weld at a time, I worked the new panel into place, making sure to move around so as not to overheat the panel.

After grinding that off I came back and filled any pinholes. Unfortunately, this turned out to be the worst panel I've ever done. Everything was fine until I was grinding. I barely did any grinding and immediately the metal began to overheat and shrink. I wasn't able to touch the metal quick enough without it overheating. My best guess is that this is because the metal was already pretty thin in this area. I would let it cool but nothing worked, the more grinding I did, no matter how slight, the more it shrank. When I took the panel to the bodyshop he said he thought they could hammer and pull most of it out. I strongly considered cutting it all out and starting over because I was very unhappy with the result but he said that he could fix it.

I took the head for the '31 to a local guy that is one of the best welders in the area and does a lot of farm machine welding. Fortunately, he was willing to try to take on the job. He machined the bolt hole bosses down and made specific washers for each hole and then machined the bottom of the head of each bolt so it would have a smooth mounting surface. I also ordered a new head gasket.

An old trick I learned for getting head gaskets to seal on old cars and trucks was to give them a quick coat of spray paint.

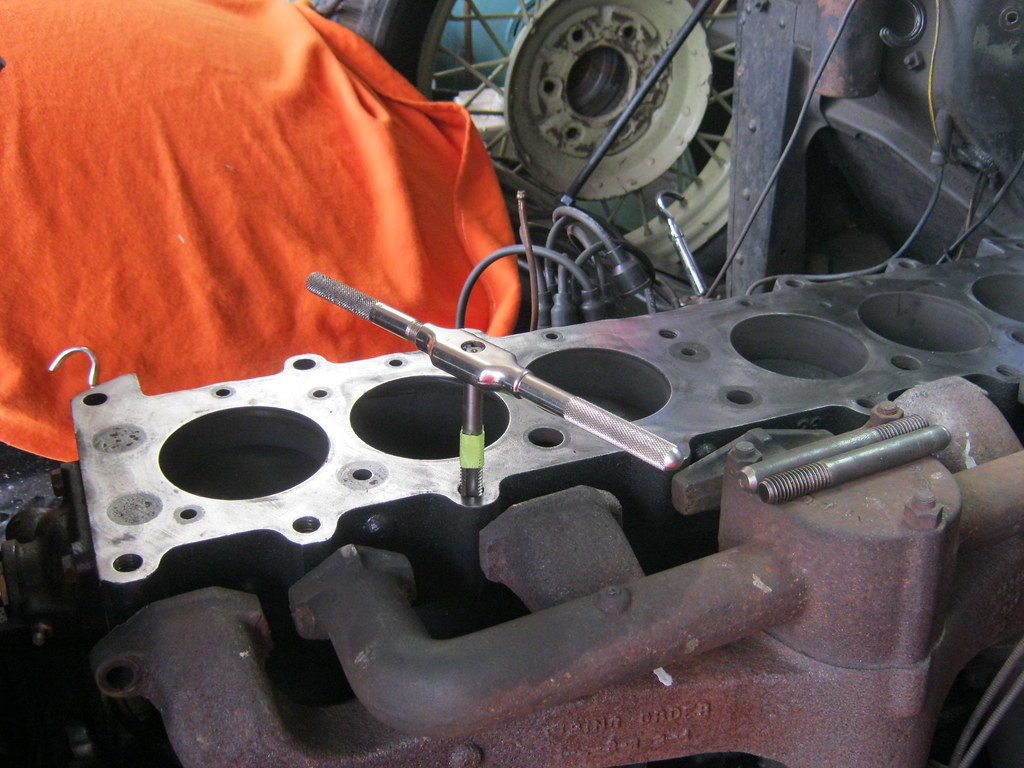

I chased all of the threads with a tap to remove the gunk.

Here's a shot of how much was in one of the holes. Some were worse, some were better.

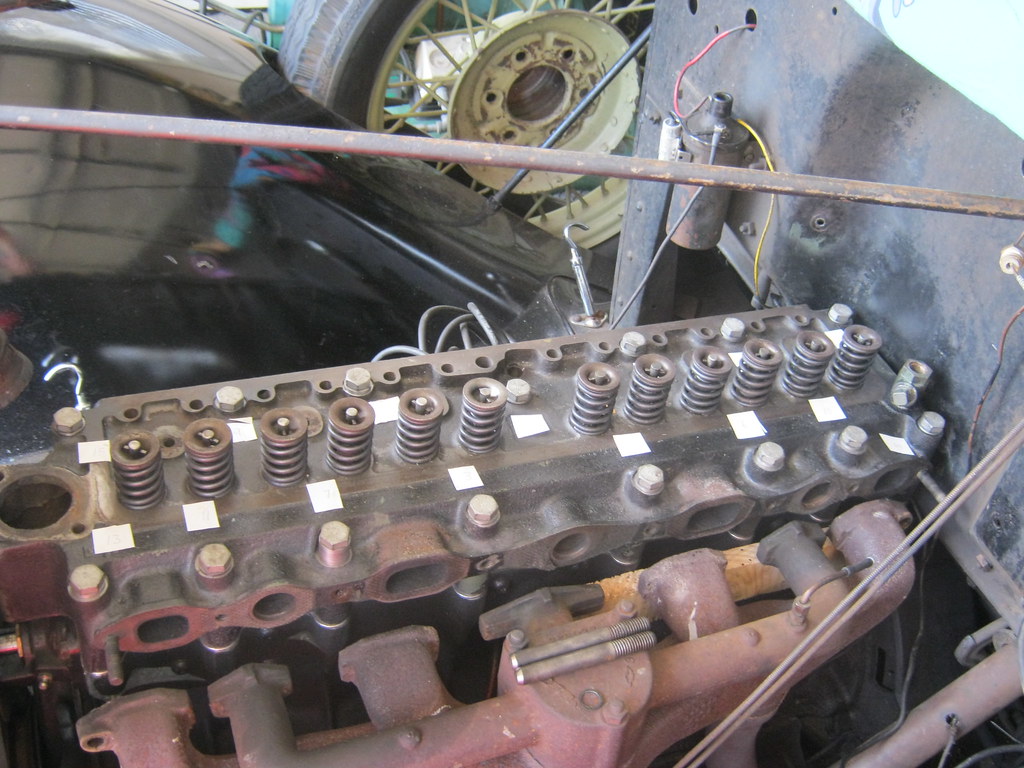

My brother-in-law came over and helped me sit the head back on the block. I used two dowels I made the last time I had the head off that I made from two old bolts that I cut the heads off of. I oiled each bolt and installed it by hand with its particular washer. I numbered each bolt to ensure I didn't make any mistakes in the torque order.

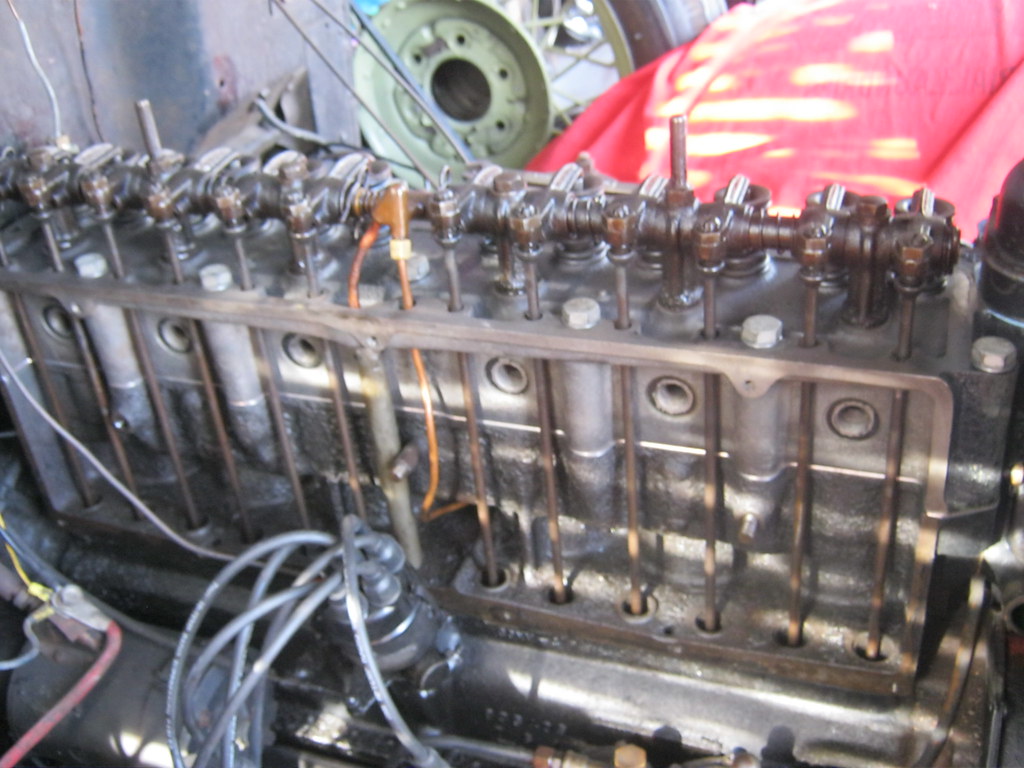

I installed the pushrods, rocker arm assembly and oil line.

I had to make sure I got this oil return tube lined up as the head was being set into place.

I set the valves cold by adding .002 to the intake and exhaust vavles. By setting the engine to top dead center on the #1 cylinder you can set a certain number of the valves and then when you are done with those you turn the engine to top dead center on #6 cylinder and can set the remainder of the valves. Fortunately a hand crank allows you to do this easily and with more precision than bumping the starter.

I labeled each valve to be set and whether it was an "I"ntake or an "E"xhaust, to make sure I didn't make any mistakes. It's easy to get confused. Intakes normally set at .006 and exhaust at .008. I forgot to order an intake/exhaust gasket, so that was the end of my progress until it comes in the mail.

The radio system in The '57 had not worked correctly in several years. A long time ago I had installed a subwoofer along with an aftermarket radio and speakers. The system began making a popping noise at specific intervals and the volt meter would jump up and down each time it did. It seemed most likely that the amp and sub had a problem so I removed them and rewired everything. I had installed a DVD player years ago and later had installed another one after the voltage surge, I believe, ruined the old one. The reason I installed a DVD player was not for the purpose of watching movies but because a dual layer DVD can hold much more mp3 information than a regular CD, which would allow me to keep more music on one disc. Also, I found that if you have 500 or so songs on a playlist playing on random and you decide to listen to a different type of music you have to interrupt that playlist and then when you start it over you have to listen to half the songs over again. To allow multiple playlists at the same time I have a DVD player that plays mp3s, an SD card that plays mp3s, a USB port that plays mp3s and an Ipod that, of course, plays mp3s.

Because the DVD player has a screen I mounted the radio on modified cabinet drawer slides so that it could pull out and the screen can flip up. I think I built this around 2007.

At that time I also installed an external Ipod dock which allows the Ipod to play through the radio but is controlled through an extra controller. This allows the Ipod to be hidden away somewhere. I don't have a lot of pictures of the entire day it took to rewire the car, but if you imagine me laying upside down in a giant bowl of spaghetti, that's basically what it looked like. I spent several hours going over the car's wiring diagrams, the DVD/radio's diagrams and the IPod controller's diagrams to try to find the best way to make everything work together the way I wanted.

The display of the Ipod shows on a small screen under the dash.

The Ipod is controlled from this.

Two smaller speakers in the kick panels and two speakers in the rear deck.

The biggest design flaw, and complaint of those who own one, with the external Ipod controller is that it turns on every time you turn the ignition on. This means if you are halfway through an audiobook or a playlist and have it turned off and are listening to the radio, every time you turn the car on you have to remember to push and hold the power button on the Ipod controller, which takes about 2-3 seconds, and turn it off, or it plays in the background with no sound and you lose your place. I initially intended to wire it to a toggle switch that would allow me to turn it on and off when I wanted but after looking at the system I believed I had found a better way. The original AM radio was no longer functional but still had power. The backlighting to the original radio only had power when the lights to the car were on and then were on switched power depending on whether the radio was turned on or not. This meant that even if the lights on the car were on, if you turned the radio knob off, the light would go off. I ended up taking the radio pigtail apart and wiring the radio power back up but I supplied the radio light with power anytime the ignition was on, rather than only when the lights were on. Then I took the radio light bulb assembly apart and soldered in a connection that allowed me to plug in power for the IPod controller. This means that now when I want to listen to the IPod I just have to put it on AUX and then turn on the knob on the original radio and my IPod comes on. It goes off with the ignition to the car and comes on with it as well, unless I turn the original radio off, then it doesn't come on with the ignition. So I basically wired the IPod to turn on and off with with the original radio knob and it stays on when I want and stays off when I want.

Then, the puddle I noticed under April's Suburban a while back.... came back. It was antifreeze again. After tracing its route I found that the last time I didn't just have one problem, I had two problems. The heater hose fitting and intake manifold gasket were both leaking, but they were leaking together into the same part of the engine. The 5.7 Vortec engines were known to have a faulty intake manifold gasket design and it is common for them to be a problem. My research showed that a new metal type of gasket has been designed to fix the problem of the old plastic design.

The Suburban is a lot newer than the vehicles I'm used to working on and it's seemingly infinite number of sensors was pretty intimidating, about as much as going from working on the Spartan engine bay of the '57 to the mass of wires and hoses of The Wagon. After doing hours of research online I dug in and began taking things apart. I took pictures of literally every step along the way and every plug I disconnected. In the end I had over 100 pictures that I used to help put everything back to the way it was.

This process took me about 2 days and involved a lot of sitting in the engine compartment. I'll skip over the minutiae and give the end result. Here everything is removed, old t-shirts are placed to keep dirt out of the engine and I cleaned all of the mating surfaces before the new gaskets were installed. One tricky issue is that the distributor must be removed, however the timing cannot be set with the distributor. The timing must be set with a computer scan tool. This means that the distributor must be placed back onto the engine in exactly the same position it was removed, which necessitates accurate markings on the distributor, the firewall and the rotor button as well and taking plenty of pictures.

One thing I cannot stand is needing a tool and having to take time to look for it in the middle of a job. I prefer to take the extra time and keep everything organized as I go because when I need a tool I want to know exactly where it is.

After installing everything I made a hose to flush out the coolant system. I changed the system from the Dex Cool type antifreeze that GM used to the conventional green antifreeze that they should have used. The system can run on either, but they cannot be mixed or they will turn into a substance that will ruin your vehicle. I hooked the hose I made into the heater hoses and then connected it to the engine block and flushed them both. Then I flushed the radiator.

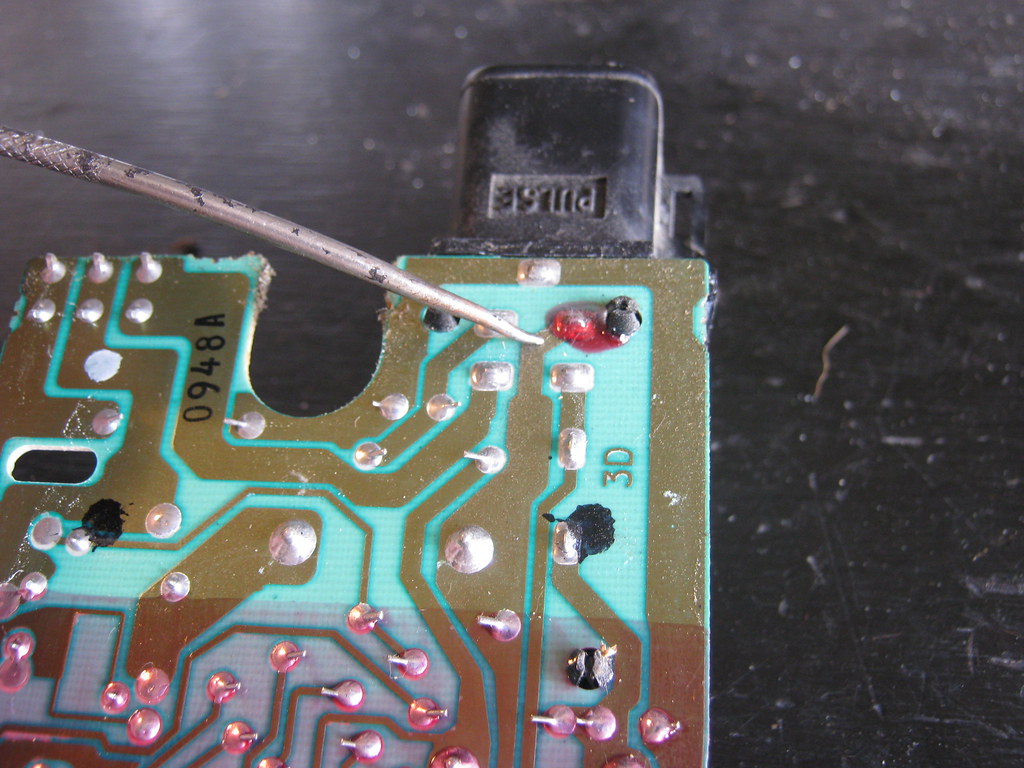

The wipers had also not been functioning properly so I addressed that as well. According to what I found online the probablem of the wipers not cutting off when they were supposed to and then parking at random places on the windshield was because of solder points on the wiper pulse board cracking. I removed the circuit board from the wiper motor.

There were about 9 or so solder points that connect where the wiring harness plug goes into the board. These points had cracked, though the cracks are too small to be seen in the picture. I used a dremel to grind away the protective coating, resoldered them and then coated them individually with dielectric grease. So far, this has fixed the problem.

Back to The '31. Though I had ordered the intake/exhaust gaskets for The '31 the week prior, I hadn't had a chance to install them because things on other vehicles kept breaking. It almost became a joke to see what was going to go wrong next to keep me from fixing The '31. I used this gasket cleaner tool that a friend gave me a while back and it worked amazingly well.

I cleaned the mounting surfaces, got the gaskets on, mounted the intake/exhaust manifolds, filled the car with antifreeze and started it. When it warmed up to operating temperature, I reset the valves. So far, everything seems to be OK, but it's too early to call. I'm going to go through a few more heat cycles and miles and then retorque the head and retighten some bolts for a final time. If you notice the 3rd headbolt from the left, you'll see the extra long spacer needed to replace the large, cracked boss that was here before the machining.

Subscribe to:

Posts (Atom)