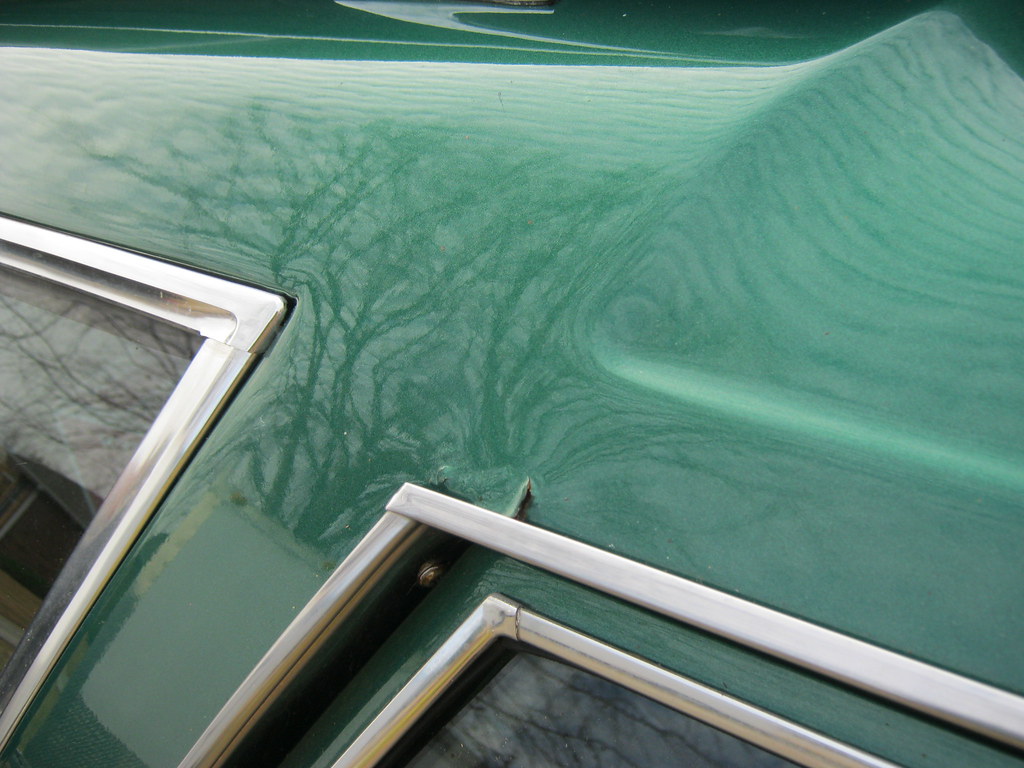

Today, it was time to tackle some rust issues. First up in the passenger side drip rail area. These cars are prone to issues in this area. Starting on this is a huge mental hurdle, but the only way it gets done is to jump in and do it. Here is the afflicted area.

The first step was removing the drip rail moldings.

After taping off the surrounding area for protection I cut open the tin can.

Here's the rust on the inner structure that caused the problem

Here's a wide shot of the area

I used a couple different wire brushs on the drill to clean the area thorougly

Then I covered everything with weld-through primer, making sure to coat everything I could reach inside the roof area. I let it dry while I went to lunch and when I came back I coated everything with the paraffin wax rust preventer.

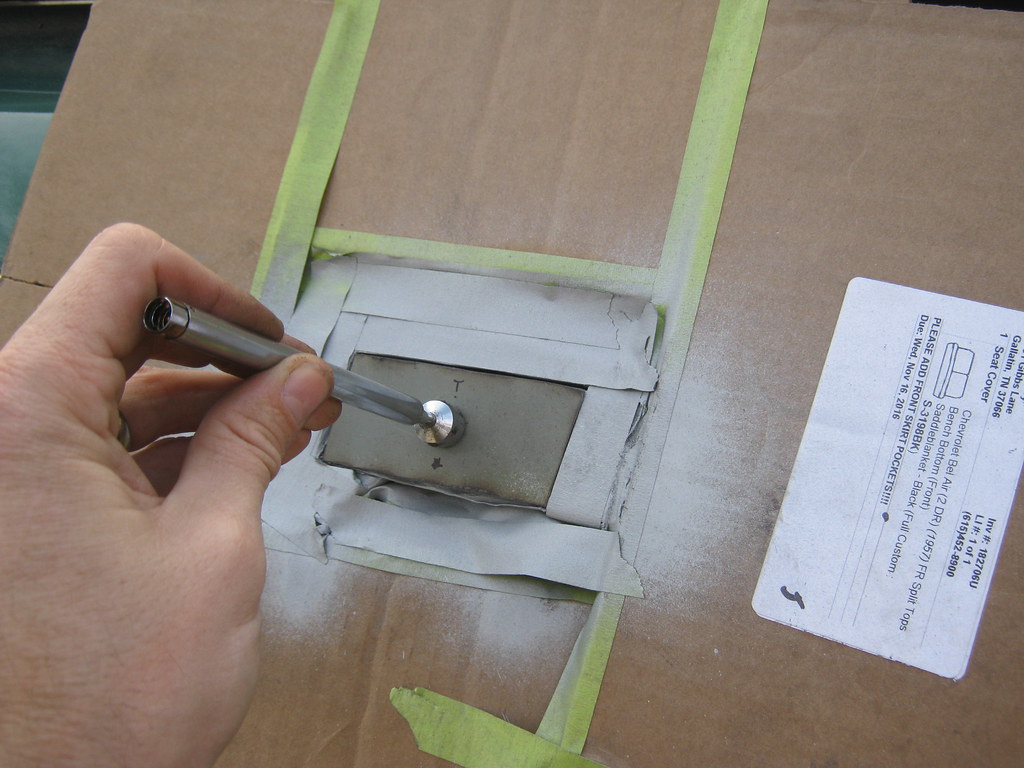

I used the old piece to make a template and cut out a new piece.

Test fitting the new patch

After I welded the top I rolled the bottom lip so I could weld it as well.

To weld the bottom it was necessary to open the door, which means I had to make sure I protected the original seats and door panels.

I ran into a problem on the left side. When I attempted to weld the metal on the car would instantly melt away like butter and made a very different sound than it normally does. The problem was that this area was full of lead. This was the area the factory attached two panels together and they used lead as body filler to smooth the transition.

I used the wire brush to remove the paint and primer and see what areas were coated with lead. You can see lead here as the area with scratches. Lead is soft and the wire brush scored the area.

The angle of this picture unfortunately doesn't show the depth, but I used a grinder to grind away the lead down to bare metal which gave me something to weld to. The actual metal was about 1/8th inch deep so I had to slowly build up weld material to the right height to connect the patch panel. Then I put the end of the spray tube into the holes at the bottom and filled the cavity with the paraffin wax rust protector.

I covered everything with primer to protect it until I'm able to get back to it.