When Woodson died almost a month ago his wife gave April and I his 1997 Lumina. Dad had sold this car new and when it was traded in Woodson had bought it from the dealership. It has the 3.1 engine with 136,000. We had been needing a car for April to commute back and forth to work and this was perfect timing. I remember washing a million of these things when they were new on the lot at the dealership. The white ones used to get black streaks that would run down the plastic bumpers if they sat on the lot for any period of time and the only way to get it off was to wax it off. There's a good chance this is one of the ones I lamented so many years ago. The car needs a few maintenance items so I'm working on addressing them.

Progress has been very slow. Due to sickness and weather, I have not even had a chance to move the car from where we parked it in the driveway the night we went and picked it up. Sickness has been spreading around everywhere like the plague and our family was not immune (pun intended). April was sick and both girls ended up with double ear infections and fevers that seemed to go away and then come back. I also ended up getting sick. Rain, snow and cold weather also set in.

Despite the windchill being near 3 degrees today I tackled some of the issues. I replaced the belt tensioner and belt. I also get a new PCV valve, spark plugs and plug wires, air filter and wiper blades. The service engine light was on and it was showing two codes. One was for the EGR valve and the other was for the EVAP canister purge solenoid. The EVAP canister is what I have always called a charcoal canister. I went online and bought a near mint set of shop manuals for $25 and searched online for the best method to solve these issues.

I had a code P1406, which means the pintle on the EGR is not functioning correctly. A common issue to address when an EGR is bad is the EGR passageway. If unaddressed, the carbon deposit buildup in the passageway can cause the new EGR to fail quickly, which was probably the case with this car. The EGR, which appeared to be a newer replacement, was bad. The EGR (Exhaust Gas Recirculation) is programmed to open after idle, take some of the exhaust gas and put it back into the engine to burn off some of the hydrocarbons, thus providing cleaner emissions. On these cars, the EGR is a solenoid that opens at various intervals depending on engine conditions and allows the exhaust to enter the intake manifold. It has a position sensor to tell the computer when the solenoid is not opening to the correct extent. There are several methods for bench testing these if you don't have a scantool which will allow you to test it in the car. Apparently, these cars are bad about building up carbon in the EGR passage, which will throw codes and cause EGR faults. The proper way to fix this problem is the remove the throttle body and clean out the passage.

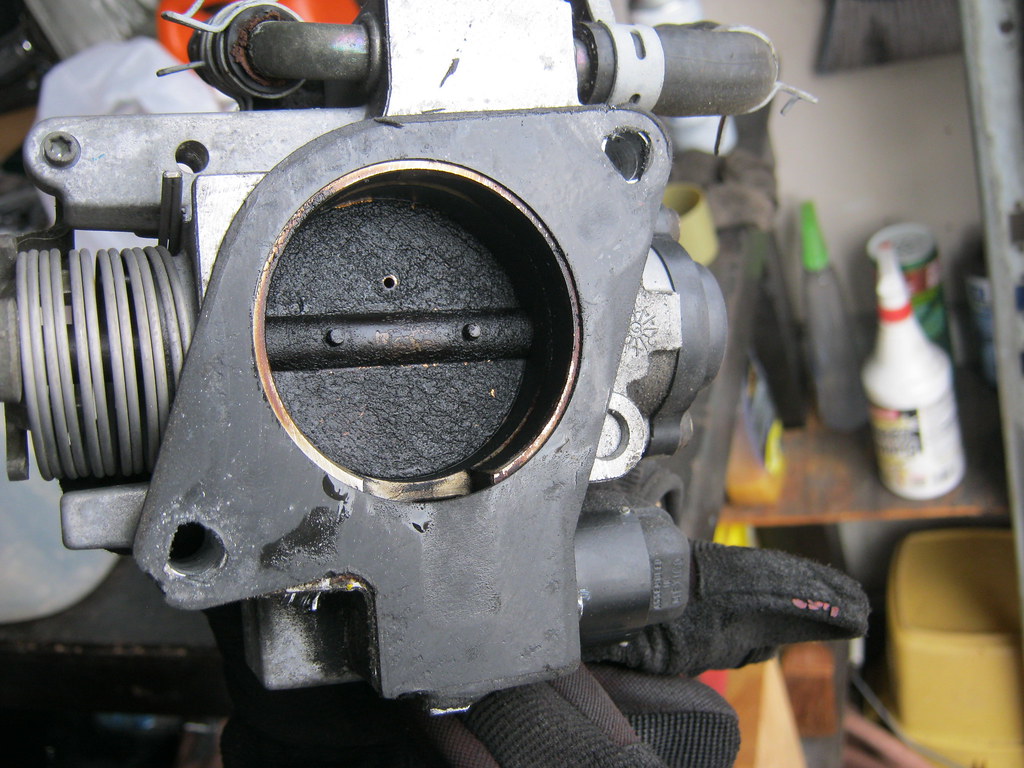

I didn't take as many pictures as normal because the temperatures were painfully cold. Also, the driveway was relatively clear except for, literally, one patch of ice exactly where I needed to put my feet so I was constantly slipping while leaning over trying to work. It was hard not to see the comedy in the situation. These pictures looked clearer when I took them but when I transferred them to the computer they were blurry. Here is the carbon buildup at the EGR passage.

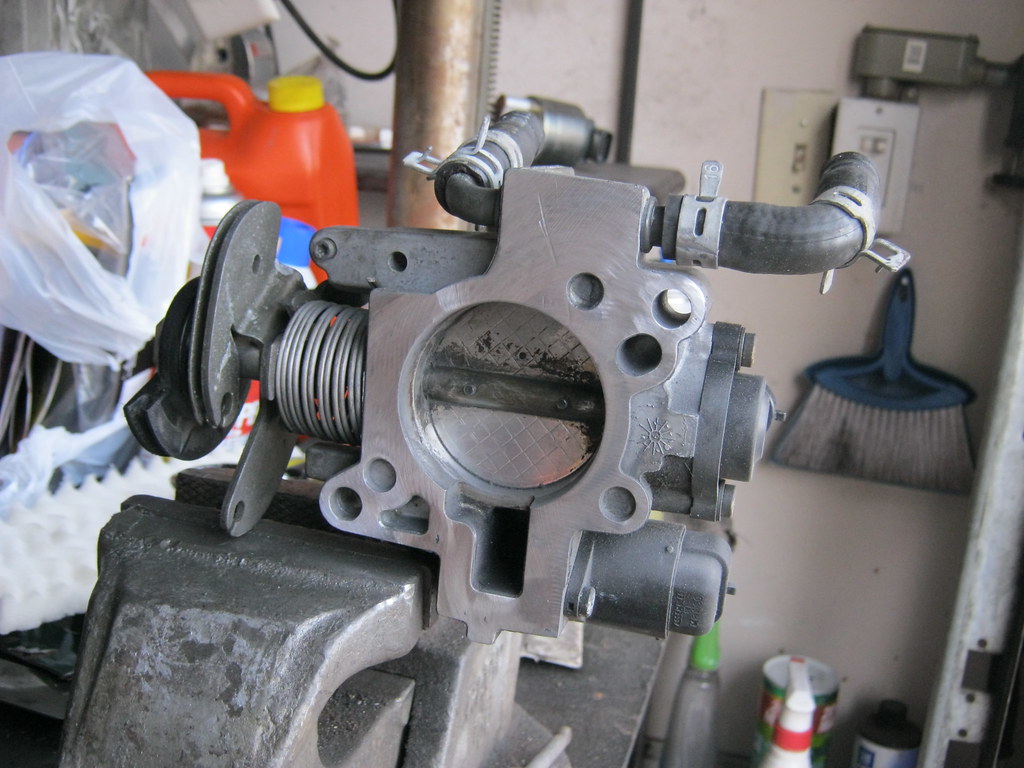

After using compressed air, a bunch of wire, a small pick and some throttle body cleaner I finally was able to clean out the passage from both this side and from the other side after removing the EGR valve. The passage hole from this end is smaller than it appears. Inside what is shown here, the hole is only about the thickness of one or two coat hangers. I attached a pipe cleaner to the end of my drill and it broke off inside the passageway from the EGR side. I was afraid I would have to remove the entire intake to get it out but fortunately it eventually came out.

Carbon buildup on the throttle body butterfly can cause the pedal to stick so it's important to clean this area as well.

And make sure to completely remove the old gasket.

The only part of this project that isn't straight forward is that when you remove the lower right nut on the throttle body and remove the hot water heater bracket there is still a stud under it which holds the throttle body to the intake.

Making sure not to break any of the old plastic in this intense cold can be a challenge but thankfully nothing broke today. There were only five connectors to put back and each one is shaped differently so there's no way to mix them up. Next will be the spark plugs, wires and brakes.