Progress on the station wagon has been very slow for sundry reasons, some of which I'll address later. One of the reasons was that I needed to get a used truck. After looking around for a while I decided to spend less money and get my old K5 Blazer back on the road. It's been off the road for 8 years after I loaned it to my relatives. During that time, my mother also backed over it and caved the passenger side door in. I needed to add a trailer hitch so I purchased one from U-haul and installed it. It was easier to install than I had thought and fortunately didn't involve removing the gas tank. It also has a 4" lift that I bought used from my friend in 2006 who was taking it off of his K5 to get a bigger lift. It was taller than I wanted but it was all I could afford at the time. The pinion angles are all wrong so I've ordered new 3" lift springs and once those come and I get them installed I'll work on getting all the driveline angles pointed where they need to be. The girls love getting to ride in it and were shocked to find that trucks can drive in creeks.

Another setback I had was that The Caprice still had a leak around the windshield and floorboard and I couldn't find it. It was leaking at the top of the windshield and running down the inside of the A-pillar. To make a long story short, the company that installed the windshield didn't put enough sealant and it was leaking at the top. That issue took a long time to track down and fix, and unfortunately, I had the new windshield installed in 2015, and the car was stored and not driven until the LS swap started, so there was no way to go back and hold the company liable. In the process of removing the interior trim again, I accidentally broke one of the brittle, plastic pieces. I had a plastic welder from a previous project but had never used it because plans changed so this was my first time of performing plastic repair.

I used paperclips to reinforce the repair. It's ugly on the back, but is virtually unnoticeable when installed on the car.

Some of these pictures are from earlier in the year when the weather was cold, before all of the delays. I won't have as much detail on some of these steps because they happened months ago. Since my youngest daughter had helped me with the intake process, I let her have the fun of taking all the tape off.

We moved over all of the fittings from the original intake to the new intake.

I sent all of the front accessory brackets, and a few other pieces, to be powder coated. I also had them sandblast the exhaust manifolds. I believe by the end there were a few more pieces added that aren't pictured below.

After looking at different options I decided to paint the exhaust manifolds with a product from Eastwood. It's a heat resistant coating that is a thin liquid. I applied a few coats with sponge brushes. This stuff is supposedly supposed to resist rusting and flaking off, so we'll have to wait and see.

First I needed to roll the car out and degrease everything under the hood. Being able to work inside during the cold weather is a welcomed change from working on The Caprice out in the elements.

A lot of scrubbing and brushing and rinsing took place.

And then some more degreasing, and scrubbing and brushing.

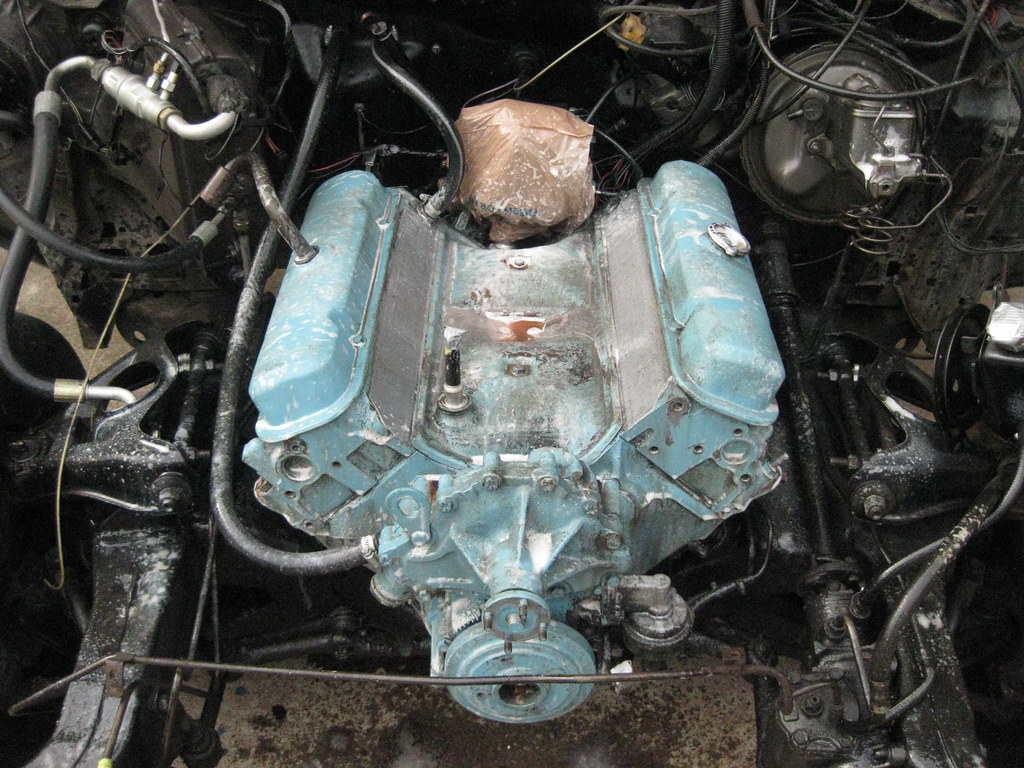

Getting the car pushed back in the garage wasn't too hard because I happened to have family in that weekend and they helped make it easy. After the degreasing I cleaned the engine and prepared it for paint.

I've never been entirely happy with the rattle-can primers I've used in the past so after searching around a bit I decided to go with a two part, heat-resistant primer from Eastwood. It comes in a rattle can, but must be punctured on the bottom to allow the two parts to mix.

I still had a few cans left over from the first time I painted the engine several years ago. Unfortunately, I didn't realize that they have since discontinued this color. I would have had plenty of paint left over but unfortunately something happened to my last, completely full and unused can and none of the paint will come out at all. Fortunately, I had just enough, and I mean just barely enough, to get the entire engine painted. I couldn't just go buy another can because the colors wouldn't match.

I then rolled the car outside again to apply some Ospho rust converter on the frame and suspension parts. I cleaned the frame and applied the Ospho and this is where things went sideways. After finishing I had April help me push the car back inside the garage. I'll try to explain what happened next: I was standing in front of the front, passenger tire with one arm pushing on the firewall next to the heater box and one hand pulling on the frame. Right as the tire was about to go over the lip on the garage entrance my foot slipped on some of the cleaner that was mixed with water on the concrete. This caused me to slip and fall down the front wheel and slide down the front of it, which caused my arm that was extended forward to be pushed in a direction it's not meant to go. I literally heard the tearing sound in my shoulder as I fell. Long story short, I did not end up needing surgery, however I was unable to use my arm for most of 6 weeks, if not longer. I was able to get the car back in the garage by borrowing a four wheeling and pushing it back in.

I won't go into details, but my arm wasn't the only health/injury to cause delays, so skip forward however long and the frame is now painted. I also have to say that the delay also killed some of my momentum and I found it hard to get the motivation to start back on the wagon; There are always other projects needed to be attended to. After the picture below I removed all of the wiring and stripped the firewall. I will repaint the firewall and after that I'll go back to getting the doors adjusted properly, which I have to do before I begin to reinstall the front clip.