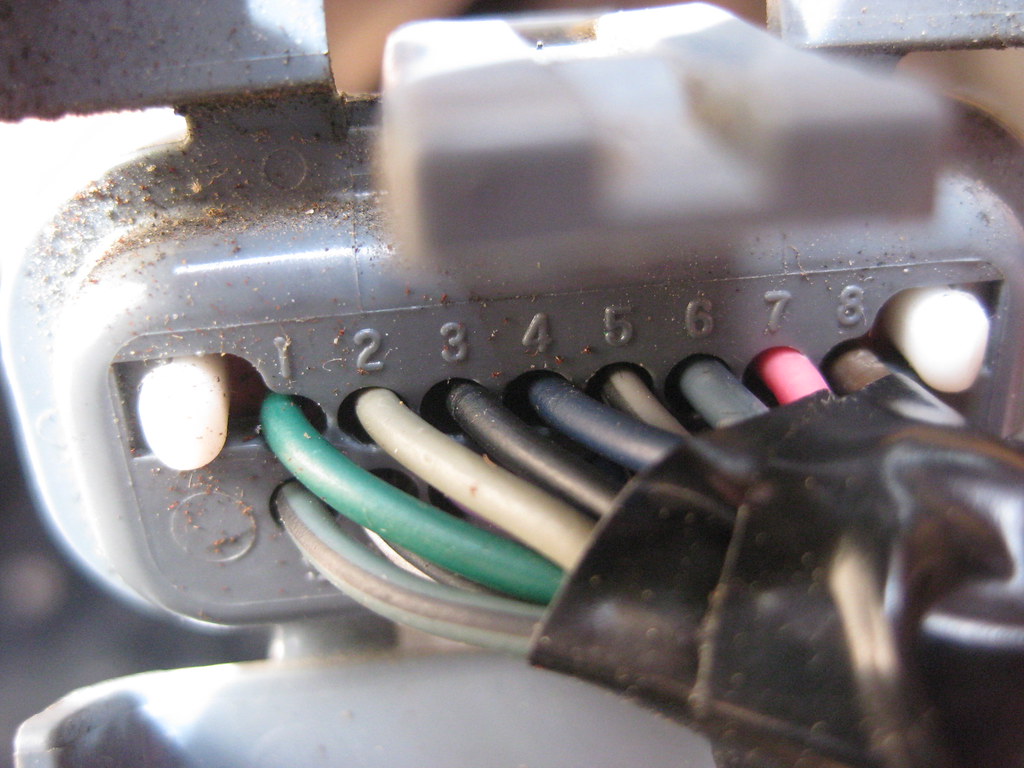

Unfortunately the pedal was still not working. I tested the sensors on the pedals and I tested the TAC module and found them to both be working properly. Since I had de-pinned the TAC module connector to fit it through the firewall I suspected that may have been my problem. Even though I had taken detailed notes which seemed to be correct I searched and searched to find the correct pinout for this connector. As it turns out they were all correct. Shortly before I began tearing into all the other components, like the throttle body and motors, all the wiring, the pedals sensors and the TAC module and related wires and connectors, I happened to read online one persons experience of having a non-functional pedal because they hooked the pedal wires up after the battery was connected. I had connected the battery first as well so I decided to give this a try and disconnected the battery and hooked all the pedal wires up before reconnecting the battery and sure enough, the pedal worked perfectly. That was a huge relief. Below is the TAC module connector from the PCM which I had de-pinned.

I went over and over these wires time and again trying to find my mistake.

I haven't driven the car yet, but just idling in the driveway I find it to be way too loud. I'm going to wait until I drive it to see what it sounds like, but I've been looking into other muffler options. I will say that I seem to be in the minority in that I really hate the way new LS Corvettes, Camaros and basically anything new sounds at all, even when quiet. The true-duals with no crossover give the exhaust behind the car a sound I kind of like. Hearing each pipe on it's own gives a stereo sound that reminds me a bit of old small block Chevy's from the 60s.

It was so cold on Saturday that paint wouldn't adhere properly and it definitely wouldn't dry in any kind of timely manner so I cooked up a batch of air intake brackets.... and April says I can't cook! This was the first time I've ever heated paint in the oven, but it did worked very well, even though it didn't smell super great in the kitchen.

Friday night, when we took the PCM to the tuners, I began feeling sick. Saturday morning I felt really bad, but I was so close to having the car finished enough to drive around the block I was determined to finish. Despite my determination I had given up on fixing the pedal so I took all the layers of clothes off, no small feat, and sat at the computer trying to research why the pedal wasn't working. When I found the battery connection issue I had to suit back up and go give it a try. When it actually worked I was determined to get back out and at least drive the car around the block. I was doing the typical rounds of addressing any of the existing leaks one by one. Both transmission lines were leaking from the case. I got the top one stopped, but they were very hard to get to and it was really hard to tell from the odd angles I was at how hard I was pushing, and I also felt really really bad. The very last thing on the entire car I had to do before I could test drive it around the block was tighten the lower line. The thought of actually getting to drive the car seemed like too much fun, so I decided to strip out the threads on the transmission case. Needless to say, that ended any chance of driving the car that day.

After being sick over New Years I was able to get back to work on the car the following weekend. After work one night I double checked to make sure it was the case that stripped. If I was lucky, maybe just the fitting stripped and I could replace it. I had no such luck and the case was in fact stripped. I realized it would take me a long time to remove the entire transmission and fix the threads so I called a local shop and asked if they could do it. I ended up ordering a helicoil kid and they said they could drop the transmission and fix the threads. This will probably take them a day, where as it would probably take me a month or better to completely finish this project given the time I have available. I decided to add some connectors on the transmission line so that I won't have to remove the lines from the case anymore. Since the threads were stripped on the lower line I was able to cut the line and pull it out from the case. Then I put a double flare and connector on the line.

I know I sound like a commercial for this tool but I really love this thing. I was worth every dollar. I was able to flare all of the lines on the car, even in the cramped quarters, and every flare turned out practically perfect. I even remembered to put fittings on all the lines before I flared them, though I did have a close call.

The pressure line from the transmission had fluid running out of it while I was trying to flare it. It looked like a scene from the movie Psycho.

Now the transmission shop will have an easier time with the installation and I won't have to worry about this problem ever again. Of course I could just not do something stupid like strip the lines out anymore, but that's probably far too high of an expectation.

Before the PCM was reprogrammed the computer was causing the engine to do all kinds of bad things, one of which was run super lean, which caused the exhaust manifolds to glow bright cherry red. All the paint I had spent time applying to them was burned off immediately. Also, all of the loom I had installed that was anywhere near the exhaust melted. I didn't have any loom or wires touching the exhaust, but it still melted it anyway. Nothing is more fun to remove than melted plastic. The black tape seemed to hold up decently in several places.

After removing all of the old charcoal I went to two franchised parts houses which have become practically useless. Our last independent parts out went out of business recently and I really miss it. After my third stop I was able to find some heat wrap tape. I applied it to the areas which run near the exhaust and manifolds. I removed the starter to make getting the oil sender wire easier. This is absolutely faster than trying to get it disconnected with the starter still in place. These LS starters are much easier to take off and put on than the old small block starters were.

The pipes hopefully won't ever be getting that hot again, but just in case they do this stuff should protect it. The wires themselves and their insulation was not damaged. For the price they charge for the small amount of this stuff you get it had better work.

I finally made a decision on what kind of vapor filter to get for the gas tank. The one I found that I liked best was a stock filter from a 2nd generation F-Body Camaro or Firebird, but I also found that those have been discontinued and are hard to come by. I ended up running the hose up and over the frame and in between the frame and body like the fuel lines are run and then mounting up high between the frame and body. This is also a rollover valve, so if the greasy side ever goes up all the fuel won't run out and cause me and the car to look like the wire loom above.

It finally stopped raining so I went and got the trailer and hope to load the car soon so I can drop it off and the transmission shop one day in the upcoming week. I got the insurance updated to reflect the new modifications and if everything works as planned I hope next weekend to take the car to get new tires and then the catalytic converters installed. I also need to take it back the tuner's so we can fine tune everything while the car is running. After that I can get it emissions tested (scam) and then licensed. I have noticed some rust under the old vinyl top, which itself is in really bad shape. I talked to the body guy that repaired it last time when April totaled it and he has moved about 3 1/2 hours away. I'll drive the car for a few days to get the bugs out and then I plan to drive it to him so he can repair the roof before I have a new vinyl top installed. I still have a leak in the passenger side floorboard which I can't locate. At this point I suspect it may be coming in a hole rusted in the roof, running down the interior of the A-pillar and behind the dash, so I'm not going to install any of the carpeting or insulation until I get the roof fixed and then locate and repair the leak.