Some progress was made over the last week despite bad weather, revival at Church and work. I began removing a lot of the things that won't be needed. When I was 16 my sister bought me this dixie horn, per my request, for Christmas. I had no ability or knowledge of how to do things at the time and so I had it installed. I was always unhappy with how they installed it. After many years, it is finally ready for retirement. It hasn't hit all the notes for several years and the cheap parts have finally fallen apart.

I removed all of the original fuel and evap lines, along with this charcoal canister. This seems like it will make a good place for the ECM or new fuse box. Removing the lines took a few hours and I was glad to have safety glasses. There was loose gravel stuck under several places form where I used to drive through fields. We used to play a game called Fox Hunting. This is where a bunch of trucks use CB radios and play hide and seek. You are able to ask the person hiding questions within certain criteria and when they speak the needle on the CB moves. The more the needle moves, the closer you are to the person speaking. I always used to climb under the car and clean all the mud away, but there was plenty of gravel left.

Removing the original wiring harness was very difficult because there was so much hardened gunk over the bulkhead connector you couldn't even tell what it was except for the fact that wires were going into a mound of near rock-hard grease. I found a video on the internet that showed there was a single bolt in the middle holding it on. Once I dug a hole in the middle and found the bolt and was able to loosen it the connector came off without much trouble.

Part of the original harness out of the car. I'll have to go through this and determine which wires will need to be kept. There were two other harnesses that plugged into the bulkhead which didn't need to be removed.

I removed the original gauge cluster. It is pretty spartan as The Caprice was not a highly optioned car. Several pieces and mounting points were broken from other people working on this car before I started working on cars myself. The speedometer cable came out of the firewall without too much trouble. I was afraid the old rubber firewall grommet would fall apart but it was still relatively pliable.

I also removed the original gas pedal because I'll be using a drive by wire setup. This thing has seen plenty of time on the floor thanks to the very under-powered original 305 and the 1980's 350 truck motor replacement. The CB will remain.

Dad helped run the garden hose at different locations around the cowl as I laid inside the car and we located the water leak. Many years ago I had sealed part of this area before over on the side of the car, but someone else had attempted to seal the top of the cowl previously and there was an absolute mess. This picture was partway through cleaning and prepping the surface of where the body meets the big hole.

I taped off the area and primered where bare metal was exposed from the cleaning.

I called a friend that owns and operates a body shop and asked what I should use to seal the area. He recommended windshield urethane. The temperature was close to 100 degrees and the humidity was very high as well. It was absolutely miserable in the direct sun cleaning and sealing this area. After endless scraping, scotchbrite scuffing and grease and wax remover I was able to get some sealant down. I laid a bead and spread it just like window caulking.

This was the actual troublesome area, but I went ahead and cleaned and resealed the top as well. There's a vacuum line for the heat and air controls that can only be replaced by removing the fender. While it is off I went ahead and got a new one.

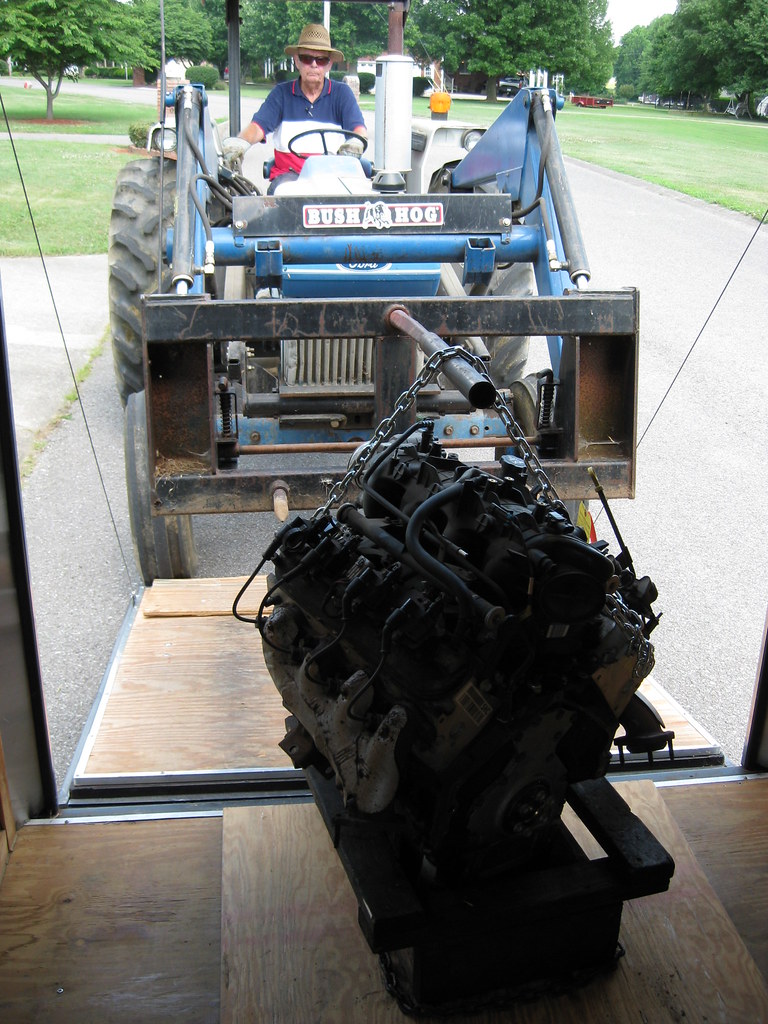

Since the first guy sold me an engine and then stopped answering his phone (classy), I located another motor. This is a 2004 5.3 LY7 from a Chevrolet Avalanche with 127,000 miles. I was also able to pick up the wiring harness, ECM, starter, alternator, power steering pump, drive by wire pedal, drive by wire module, drive by wire harness, and engine fuse box from the same Avalanche. I picked up an AC compressor from a different vehicle.

It was so hot in this trailer it was beyond description.

Fortunately Dad lives within tractor-distance of the house. The engine has been in his trailer since he made the 3 1/2 hour trip last week to pick it up. I drove his truck and trailer over and he followed on the tractor. Since the gate on the trailer lets down as a ramp, we had no way of getting the engine out. Fortunately, the engine came with a wooden stand. We wrapped a chain around it and pulled it to the very end of the trailer and with an extension pipe on the end of the hay fork we were able to reach the chain and lift it out.

Saturday, June 16, 2018

Sunday, June 10, 2018

Capricious Decision Making

April and I have been commuting to work together for almost a year and a half, but soon she will be changing jobs. We have the Lumina and the Suburban. The Suburban is a 1999 and had 78,000 miles on it when we got it. It now has 106,000 and I want to keep it as a family hauler for when we need to go somewhere with people and all the kids or for family trips. Rather than buying another commuter vehicle I've decided to put a 5.3 GM engine and a 4l60e transmission in The Caprice and the goal is to try to get this swap done as quickly as possible. I've had this car since I was 16. Though technically not my first car, it practically was my first car.

I haven't driven the car since July 4th, 2015. I remember the date because April and I went for a drive that day. I attempted to cross a creek which I'd crossed many times before, but I didn't realize they had just grated the rock bottom the day before. We didn't make it. When I later pulled the carpet and insulation to let it dry I found that the passenger side floorboard had been holding water from a leak. I've kept the car covered since that time because I knew I'd have to pull the fender to fix the leak.

April's cell phone got wet and the front screen still doesn't work. The worst part was diving under the car to hook up the tow strap.

The first order of business was getting the car to my house. I had it at my fathers house and it was pretty solidly wrapped up. It took several hours to uncover it and put a battery in it and fill it with transmission fluid and get it running to bring home.

I had blown the original 305 on the way to Baton Rouge in 2005 to be a part of The Dukes of Hazzard movie (pictured below: semi-functional dixie horn). This replacement is a stock 350 that was a warranty issue from GM. Back when my family owned a GM dealership, someone ordered a new truck sometime in the early to mid 80s and GM put the wrong timing chain on it. The people demanded GM give them a new engine, so this one was practically new and had been on an engine stand for years. We dropped it in and it served as adequate, anemic motivation for 13 years, although a somewhat hacked together hodgepodge of 78 305 and 80s 350.

I was planning on purchasing a totaled vehicle and getting the engine and transmission and all other needed components at once, but first I contacted a guy I had previously bought a 2003 5.3 from several years ago. He seemed like a really solid guy and when I asked him if he had another 5.3 he said yes. We arranged for the purchase and then he stopped answering my calls. After a week and a half I began to realize he was being a flake. It's not so much the engine that bothers me as much as the fact that I've had several situations lately in which people just won't follow through, do what they say they'll do, or show up when they're supposed to and this instance was just icing on the cake. It's difficult to try not to be bitter when you have numerous run-ins with people like this. Because I thought I already had an engine I needed a transmission. I had a friend put out the word and he found a friend of his that had a 4L60E he wanted to sell. I contacted the guy and we met that weekend and I purchased it. Now I don't need to buy and engine and transmission together, though I think that would be easier.

Everyday after work I've been coming home and working until or past dark getting the car ready to pull the engine. These have made for some very long and tiring days. One of the most time consuming parts is continually jacking up the car to access the parts I need. I'm having to keep the car blocked as much as possible because I live in a neighborhood with a bunch of older, retired people and they have continued to call codes on me time and time and time again. I had to sell a '63 Corvair project a couple years ago because of that. America: The Land of the Free.

It's been quite a while since I've worked on things from this time period. Fortunately, some things did come back to me after some thinking, like how to remove the U-joints from a GM driveshaft.

Fortunately, my long time friend who also works with me offered to come over and help when the engine was ready to come out, so after work one day we came straight home and yanked out the old 350. It went surprisingly smooth. Because our daylight is so limited after we get off work I made sure to have everything disconnected and ready to yank out as soon as we got there. The last time I pulled an engine and transmission bolted together it was a 1960 Cadillac 390 mated to the original hydomatic and a bolt broke and the engine fell. I know there's nothing special about a small block 350 and a 350 turbo, but the 390 experience was like touching a hot stove and I was paranoid it was going to fall at any moment. Grade 8 bolts are therapy for overcoming past trauma.

The exodus was without much fanfare and I tucked the old motor in the bushes with a tarp over it. I plan to weld up an engine stand with some large rubber wheels so I can roll this unit into a dirt-floored barn until I'm able to build a shop.

One thing I hate more than anything when working on cars is looking for a tool I know I have and not being able to find it. I hate it; With a passion. This results in more trips back to the workbench, but not spending 10 minutes looking for lost 14mm wrenches.

April totaled this car a few years ago. It was captial-T boned in the rear when she pulled out in front of someone. The impact broke the sealant loose in the windshield and I suspect also caused the seal to begin leaking where I had previously fixed a leak in the passenger floorboard. Though I fixed this leak the last time without removing body panels, I knew to really clean out the area and fix it properly I needed to remove the fender. It was over 100 degrees the day I removed the fender and the fender was so hot I couldn't touch it with my bare hands. Fortunately, the humidity was only 340% that day. I long for the days of having a shop and working in the shade. Not pictured: my small in stature but mighty in force squirrel cage fan keeping me from passing out.

I have to keep detailed notes on where all the bolts are located and how many shims they have or I'll never be able to get things back together. I keep photo evidence of most bolts but I make diagrams for body panels. I am envious of people who can throw everything in a big box and then get it all back together later, however I really can't stand digging in a box full of bolts hunting for what you need. I label everything and put it in a ziplock bag so I know exactly where everything is exactly when I need it.

I am absolutely, entirely out of space for storage, of anything.

Dad came over and worked the water hose as I lay down in the car hunting for the water leak. As I suspected it was the area on the far most passenger side of the HVAC box. Here's the plan for this car. I have a complete and very solid roller parts car with perfect body panels that I bought several years ago. Later, when I have a shop I plan to take this car down to the frame and and at that time I'll pull everything apart. For this season of life, I need a daily driver that unfortunately is going to have to sit out quite a bit. I'm afraid if I pull this box off I may open up a can of worms and destroy my deadline so my plan is to reseal the leak without removing the box. I'm unsure yet what I'm going to use to do so. The area of note is between vertical, left side of the cowl and the blower motor box. I cleaned and scraped all of the old silicone.

Because my original gas tank was not made for EFI, it does not have any baffles in it. Because the Caprice and Impala is the exact same car from 1977-1996, just with different bodies set on top, I was able to get the 1995 Caprice gas tank, the straps, and the heat shield from a junkyard because those cars came from the factory with EFI. Dad made some calls from his old contacts and found the tank and made the 100 or so mile trip to go get it one day while I was at work. These tanks are plastic and have baffles and fit perfectly into my car with zero modifications. I scrubbed it down because it was very nasty.

And as luck would have it, my old tank was well over half full. At least I remembered to jack it up before I let it fall on my head.

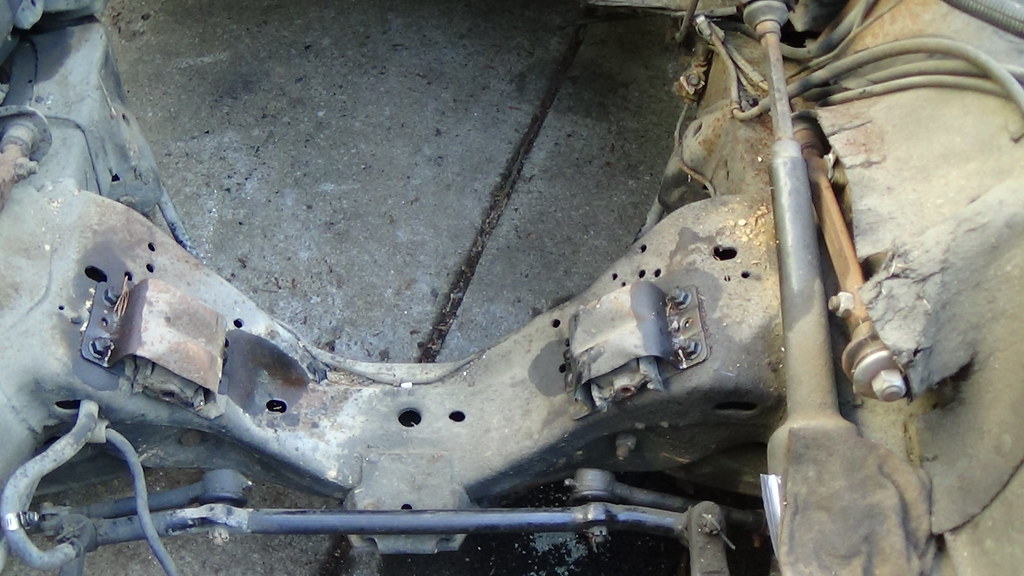

Next I removed the old engine mounts. Fortunately, LS engine swaps have become so popular that many parts exist now to help put these engines in a wide array of older cars that never came with them. I bought a kit online that is supposed to bolt right into the existing bolt holes for the engine and transmission mount and keep the correct drive line angle and spacing for a 5.3 with a 4L60E. I will need to switch to a lower profile oil pan and change out the exhaust manifolds to fit between the frame rails. The mounts came out without too much trouble, but a slightly large access hole for the bolt heads hidden inside the frame would have been nice. I suppose that's too much to ask considering GM couldn't even decide on which type of bolt to use, as half are metric (spit) and half are standard.

I haven't driven the car since July 4th, 2015. I remember the date because April and I went for a drive that day. I attempted to cross a creek which I'd crossed many times before, but I didn't realize they had just grated the rock bottom the day before. We didn't make it. When I later pulled the carpet and insulation to let it dry I found that the passenger side floorboard had been holding water from a leak. I've kept the car covered since that time because I knew I'd have to pull the fender to fix the leak.

April's cell phone got wet and the front screen still doesn't work. The worst part was diving under the car to hook up the tow strap.

The first order of business was getting the car to my house. I had it at my fathers house and it was pretty solidly wrapped up. It took several hours to uncover it and put a battery in it and fill it with transmission fluid and get it running to bring home.

I had blown the original 305 on the way to Baton Rouge in 2005 to be a part of The Dukes of Hazzard movie (pictured below: semi-functional dixie horn). This replacement is a stock 350 that was a warranty issue from GM. Back when my family owned a GM dealership, someone ordered a new truck sometime in the early to mid 80s and GM put the wrong timing chain on it. The people demanded GM give them a new engine, so this one was practically new and had been on an engine stand for years. We dropped it in and it served as adequate, anemic motivation for 13 years, although a somewhat hacked together hodgepodge of 78 305 and 80s 350.

I was planning on purchasing a totaled vehicle and getting the engine and transmission and all other needed components at once, but first I contacted a guy I had previously bought a 2003 5.3 from several years ago. He seemed like a really solid guy and when I asked him if he had another 5.3 he said yes. We arranged for the purchase and then he stopped answering my calls. After a week and a half I began to realize he was being a flake. It's not so much the engine that bothers me as much as the fact that I've had several situations lately in which people just won't follow through, do what they say they'll do, or show up when they're supposed to and this instance was just icing on the cake. It's difficult to try not to be bitter when you have numerous run-ins with people like this. Because I thought I already had an engine I needed a transmission. I had a friend put out the word and he found a friend of his that had a 4L60E he wanted to sell. I contacted the guy and we met that weekend and I purchased it. Now I don't need to buy and engine and transmission together, though I think that would be easier.

Everyday after work I've been coming home and working until or past dark getting the car ready to pull the engine. These have made for some very long and tiring days. One of the most time consuming parts is continually jacking up the car to access the parts I need. I'm having to keep the car blocked as much as possible because I live in a neighborhood with a bunch of older, retired people and they have continued to call codes on me time and time and time again. I had to sell a '63 Corvair project a couple years ago because of that. America: The Land of the Free.

It's been quite a while since I've worked on things from this time period. Fortunately, some things did come back to me after some thinking, like how to remove the U-joints from a GM driveshaft.

Fortunately, my long time friend who also works with me offered to come over and help when the engine was ready to come out, so after work one day we came straight home and yanked out the old 350. It went surprisingly smooth. Because our daylight is so limited after we get off work I made sure to have everything disconnected and ready to yank out as soon as we got there. The last time I pulled an engine and transmission bolted together it was a 1960 Cadillac 390 mated to the original hydomatic and a bolt broke and the engine fell. I know there's nothing special about a small block 350 and a 350 turbo, but the 390 experience was like touching a hot stove and I was paranoid it was going to fall at any moment. Grade 8 bolts are therapy for overcoming past trauma.

The exodus was without much fanfare and I tucked the old motor in the bushes with a tarp over it. I plan to weld up an engine stand with some large rubber wheels so I can roll this unit into a dirt-floored barn until I'm able to build a shop.

One thing I hate more than anything when working on cars is looking for a tool I know I have and not being able to find it. I hate it; With a passion. This results in more trips back to the workbench, but not spending 10 minutes looking for lost 14mm wrenches.

April totaled this car a few years ago. It was captial-T boned in the rear when she pulled out in front of someone. The impact broke the sealant loose in the windshield and I suspect also caused the seal to begin leaking where I had previously fixed a leak in the passenger floorboard. Though I fixed this leak the last time without removing body panels, I knew to really clean out the area and fix it properly I needed to remove the fender. It was over 100 degrees the day I removed the fender and the fender was so hot I couldn't touch it with my bare hands. Fortunately, the humidity was only 340% that day. I long for the days of having a shop and working in the shade. Not pictured: my small in stature but mighty in force squirrel cage fan keeping me from passing out.

I have to keep detailed notes on where all the bolts are located and how many shims they have or I'll never be able to get things back together. I keep photo evidence of most bolts but I make diagrams for body panels. I am envious of people who can throw everything in a big box and then get it all back together later, however I really can't stand digging in a box full of bolts hunting for what you need. I label everything and put it in a ziplock bag so I know exactly where everything is exactly when I need it.

I am absolutely, entirely out of space for storage, of anything.

Dad came over and worked the water hose as I lay down in the car hunting for the water leak. As I suspected it was the area on the far most passenger side of the HVAC box. Here's the plan for this car. I have a complete and very solid roller parts car with perfect body panels that I bought several years ago. Later, when I have a shop I plan to take this car down to the frame and and at that time I'll pull everything apart. For this season of life, I need a daily driver that unfortunately is going to have to sit out quite a bit. I'm afraid if I pull this box off I may open up a can of worms and destroy my deadline so my plan is to reseal the leak without removing the box. I'm unsure yet what I'm going to use to do so. The area of note is between vertical, left side of the cowl and the blower motor box. I cleaned and scraped all of the old silicone.

Because my original gas tank was not made for EFI, it does not have any baffles in it. Because the Caprice and Impala is the exact same car from 1977-1996, just with different bodies set on top, I was able to get the 1995 Caprice gas tank, the straps, and the heat shield from a junkyard because those cars came from the factory with EFI. Dad made some calls from his old contacts and found the tank and made the 100 or so mile trip to go get it one day while I was at work. These tanks are plastic and have baffles and fit perfectly into my car with zero modifications. I scrubbed it down because it was very nasty.

And as luck would have it, my old tank was well over half full. At least I remembered to jack it up before I let it fall on my head.

Next I removed the old engine mounts. Fortunately, LS engine swaps have become so popular that many parts exist now to help put these engines in a wide array of older cars that never came with them. I bought a kit online that is supposed to bolt right into the existing bolt holes for the engine and transmission mount and keep the correct drive line angle and spacing for a 5.3 with a 4L60E. I will need to switch to a lower profile oil pan and change out the exhaust manifolds to fit between the frame rails. The mounts came out without too much trouble, but a slightly large access hole for the bolt heads hidden inside the frame would have been nice. I suppose that's too much to ask considering GM couldn't even decide on which type of bolt to use, as half are metric (spit) and half are standard.

Subscribe to:

Posts (Atom)