I had printed out a couple Borg Warner overdrive manuals because the '57 wasn't kicking out of overdrive properly when I would push my foot to the floor and this was a good time to tackle the problem. Driving the car in some areas was a nuisance because in order to kick the car out of overdrive you had to push the pedal to the floor, let up off the gas and then floor it very quickly. This was not a smooth process and was annoying.

This Borg Warner overdrive unit was essentially the same no matter what transmission it was bolted behind. They basically took the tailshaft off of each manufacture's transmission and adapted their Borg Warner behind it. As a result, the manuals are basically universal for all applications of each particular make and model car. The Borg Warner model that was on the 1955-1957 Chevrolet's were a Borg Warner R10H-1.

Up in the air it went to see what was going on underneath.

According to the manual(s), the first step to diagnosing a non-kickdown-from-overdrive problem was testing the solenoid. The solenoid engages a pawl, which is what engages and disengages the overdrive. When you push the accelerator to the floor it pushes a button under the hood which disengages the overdrive for passing gear. The pawl cannot be retracted as long as there is torque still applied to the transmission so the ignition must be momentarily disrupted in order to allow the pawl to disengage. As soon as it does, the ignition can resume operation and the car continues with the overdrive disengaged. It achieves this by grounding out the ignition coil through the solenoid by using relay contacts inside the solenoid. The coil is grounded out by the contact of the pawl to the lock out shaft. Once the pawl is retracted it breaks the ground and the ignition continues as normal. To test this you must ground the ignition-cut-out on the solenoid, which is the #6 screw.....

then as the engine is running, push the button under the hood by hand. If this kills the engine, that means there is a problem with the solenoid. If it does not kill the engine, there is a list of other things to test.

Pushing the button killed my engine, which meant my solenoid was faulty. I took the solenoid off the car and went through the testing procedure to determine what was wrong with it. The strange thing is that everything tested fine with the solenoid. The pawl engaged properly. Using a test light, I determined the ignition-cut-out contacts were working properly. The spring had the proper tension on it. This was all very confusing. I continued to recheck, reread both manuals and check continuity between all the wires and connections. Everything was perfect.

Eventually, I found that an animal had been under the hood and chewed through the ignition-cut-out wire that goes from the kick-down switch under the hood to the coil. It still had contact, but the insulation was gone and some of the copper was chewed away. I also found a small footnote that said that this wire must be connected to the side of the coil opposite of the ignition switch. Mine was wired on the same side as the ignition switch, however it had worked with my previous transmission so I'm not sure what the difference is. Either way, I moved it where the manual instructed. I pulled the entire overdrive harness out of the car, cut the tape off and separated the broken wire, the one that runs from the kick-down switch to the coil, and replaced it.

This meant removing the wire from the kick-down pigtail, removing the old solder and resoldering the new wire back in place.

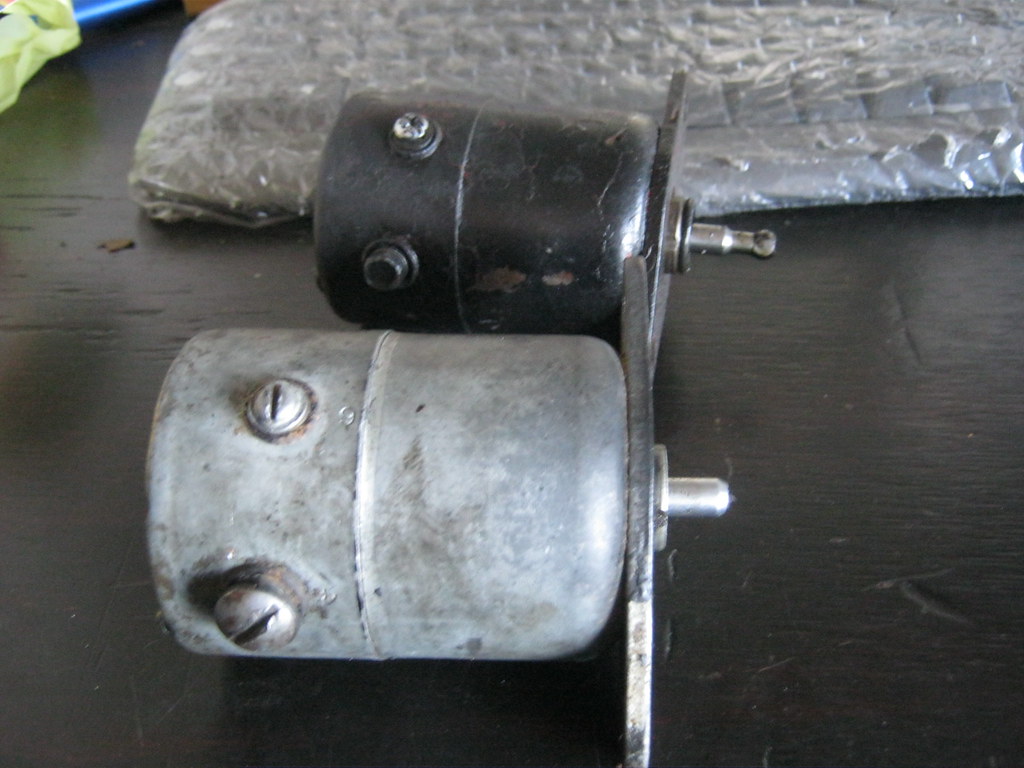

I was hopeful that this would fix the problem, but it didn't. Not knowing where to go from here I began testing all the other systems in the unit, like the kick-down switch. Everything checked out good. All the wires were good. All the connections were good, but each time I tested the solenoid, it was good. I went online to see if I could find how to disassemble the solenoid and noticed in the picture that something was off. If you look closely, you can spot it.

The end of the pawl is supposed to have a head on it. Theoretically, I knew this, but I assumed that it must be inside the solenoid and I couldn't see it. I assumed it must work in a way I didn't yet understand, but after seeing the picture I realized that mine was broken. I removed the solenoid from my other transmission and it was in tact. I got mirrors and an extendable magnet to make sure the head of the old pawl wasn't stuck inside.

I installed the new solenoid and it worked perfectly. I was glad to have that over with. Later that day April and I drove to church, which is about 37 miles away. Halfway there the kickdown feature stopped working again. I was very afraid that the new solenoid pawl had been snapped off as well. If that was the case, not only would I have to find and buy a new solenoid, I wouldn't be able to install it because obviously this transmission has a problem that causes it to shear solenoid pawls. I couldn't even imagine how that would be possible, but I didn't rule it out as a possibility because it seemed the most likely issue. We got home around 11:30 that night and I knew that if I didn't take the solenoid off then I wouldn't be able to sleep with my mind racing trying to figure out what was going on. After the first transmission going out and then having it rebuilt only to find it was incorrect, finding the new one and three years later finally getting it sorted, I was beyond dejected and fearing the worst. I removed the solenoid and found that the pawl was not sheared. I tested the new solenoid and once again found all of it's components to be in correct working order. I did remember that one potential cause of these issues was a bad connection with the wires. The only thing I could imagine was that the problem with the old solenoid had been a broken pawl but the new solenoid had a bad connection at one of the wires. Two different problems that would cause the same issue. I cleaned it a little and reinstalled them. I took it for a test drive, now around midnight, and it didn't work. As I turned around to come home it began working and has been working since. I am assuming that there was a bad connection and it finally made contact. I'm going to see if it continues to work properly and if it goes out again I'll make sure to clean all the contacts thoroughly in the daylight.