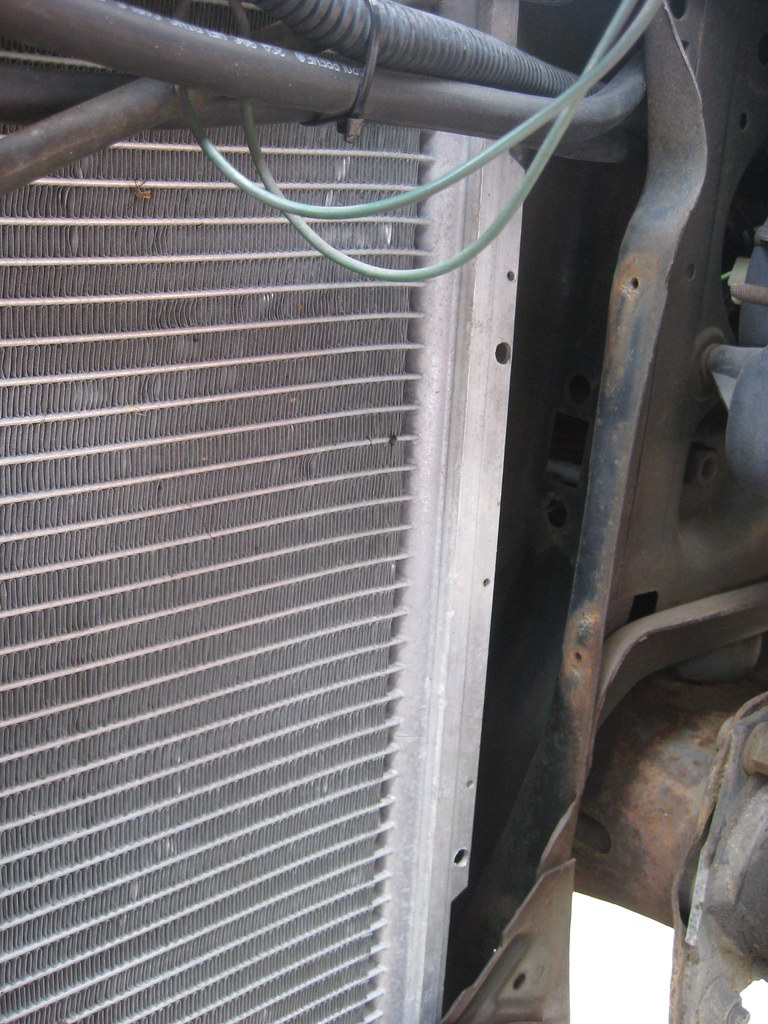

This was the gap on the driver side. Because of the angle of the picture the gap is a bit larger than it appears in the picture. Also, the mounting surfaces here will be perpendicular, requiring a right angle in the air foil.

I had anticipated the passenger side was going to be much more difficult because of the air conditioning lines and mounting surfaces, but after some test fitting I found that this side was the easiest, only requiring a single, flat piece of steel with no bends.

I started on the passenger side with some cardboard.

I made the bends, measurements and cuts.

I got this quarter panel to a new Suburban several months ago from the scrap bin at a local body shop. I picked it up specifically for this project and I'll be glad to finally get this thing out of my driveway. I transferred the cardboard to the sheet metal. I was really surprised how thin the metal is on newer vehicles.

I made the necessary bends and cuts to the metal. Watching some videos online have helped me with some techniques to get better at getting the shapes I need.

After a lot of test fitting on again and off again I finally got it to fit into place.

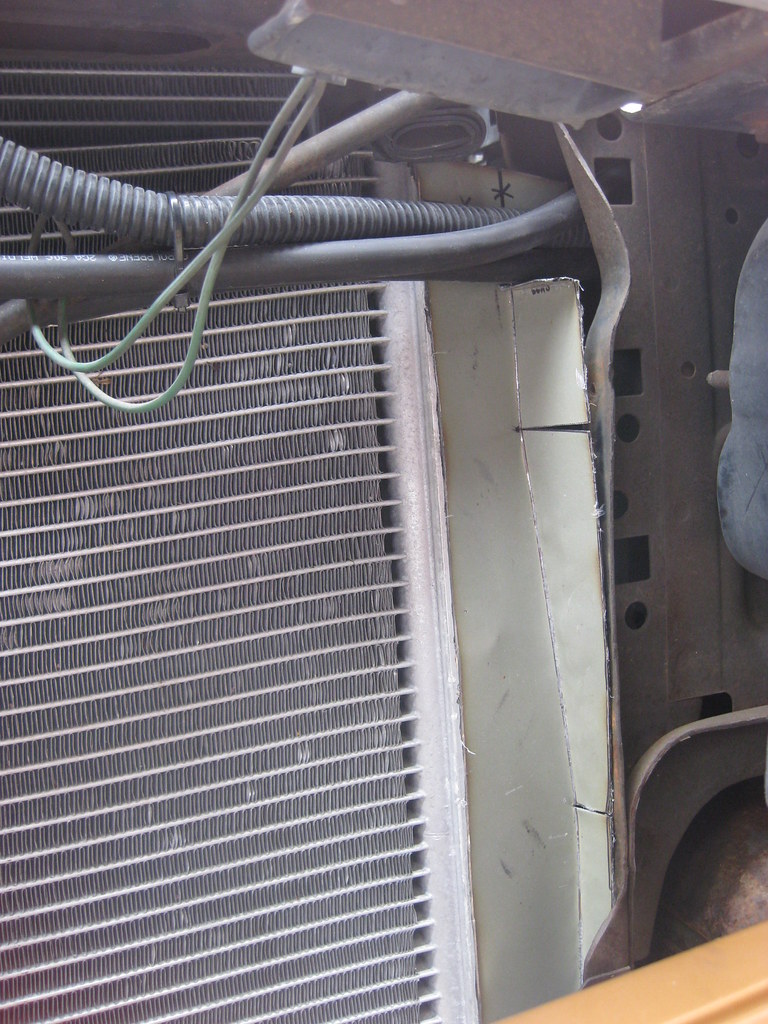

It was at this point I realized I had tackled the piece completely wrong and after some thought realized to do it right I needed to scrap this piece and start completely over. I had quite a bit of time in this piece up to this point and it was a hard pill to swallow to toss it in the scrap metal pile. Unfortunately, sometimes you just don't have your head in the right place and you do stupid things that don't make sense.

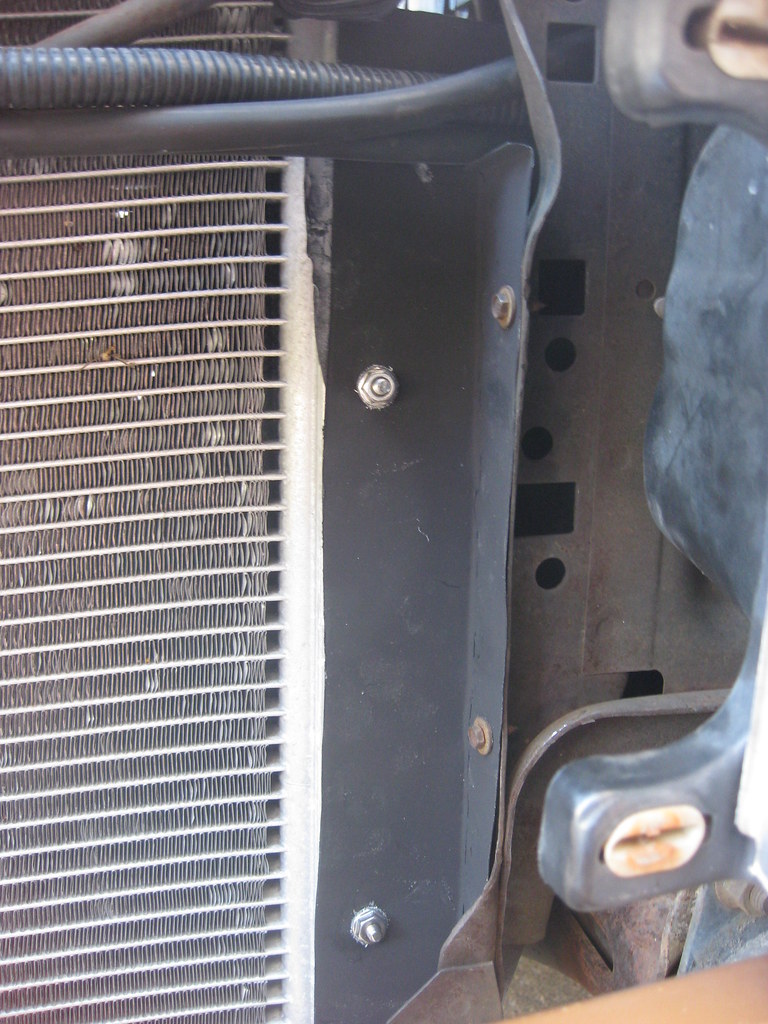

Fortunately, the new piece, when made correctly, was much less complex than the first piece so it was easier to make. I fit it into place and then marked and drilled the holes two at a time. The original setup had a smaller, less effective air foil that mounted in the same location so I reused two of those screws and screw holes.

After creating a cardboard template for the passenger side I followed the same steps to make that piece also, minus the wasting half the day making it the wrong way.

I used an old inner tube from a dump truck tire to make rubber backings for the parts of the foils that would mount to the aluminum condenser.

After the paint dried on the pieces I glued the rubber strips on.

There was very little space on the backside of the core support and getting these pieces mounted was a frustrating effort of dropping screws and then finding them. They were stainless steel so a magnet woudn't pick them up.

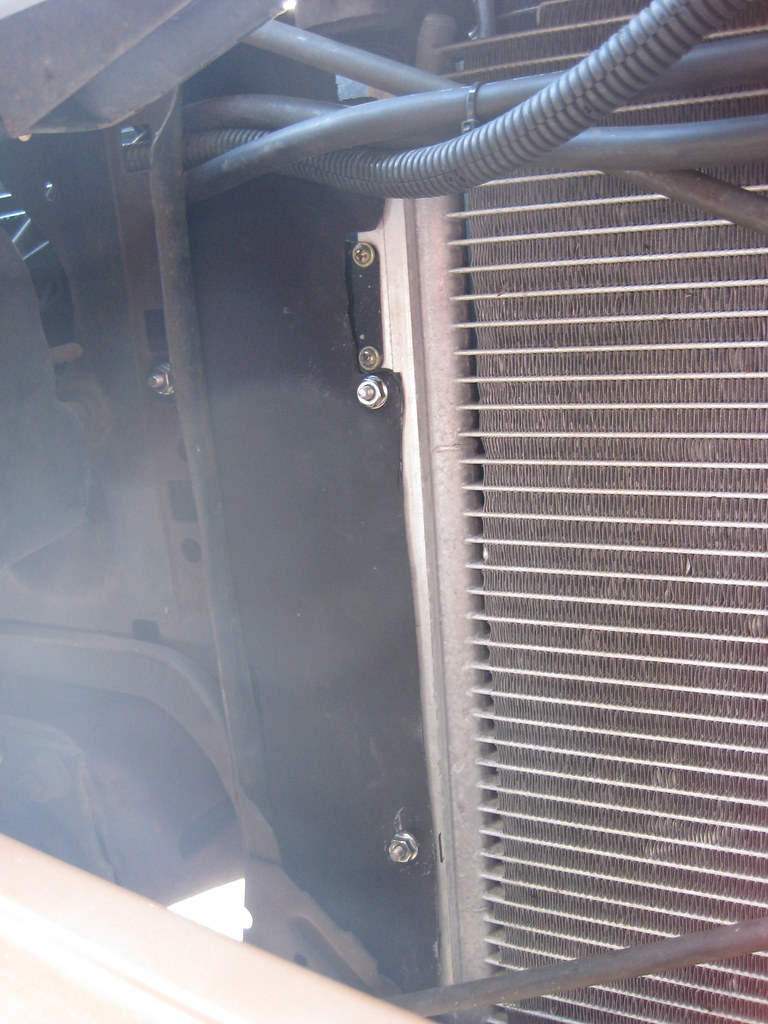

Here is a shot of the passenger side. They both turned out better than I thought they would, blocking off more of the areas than I had thought they would. As it turned out both sides were much less complex than I had thought, also.

Almost the entire area on both sides is now blocked, causing the air to be forced through the condenser and radiator. Below is a picture of the backside on the passenger side.