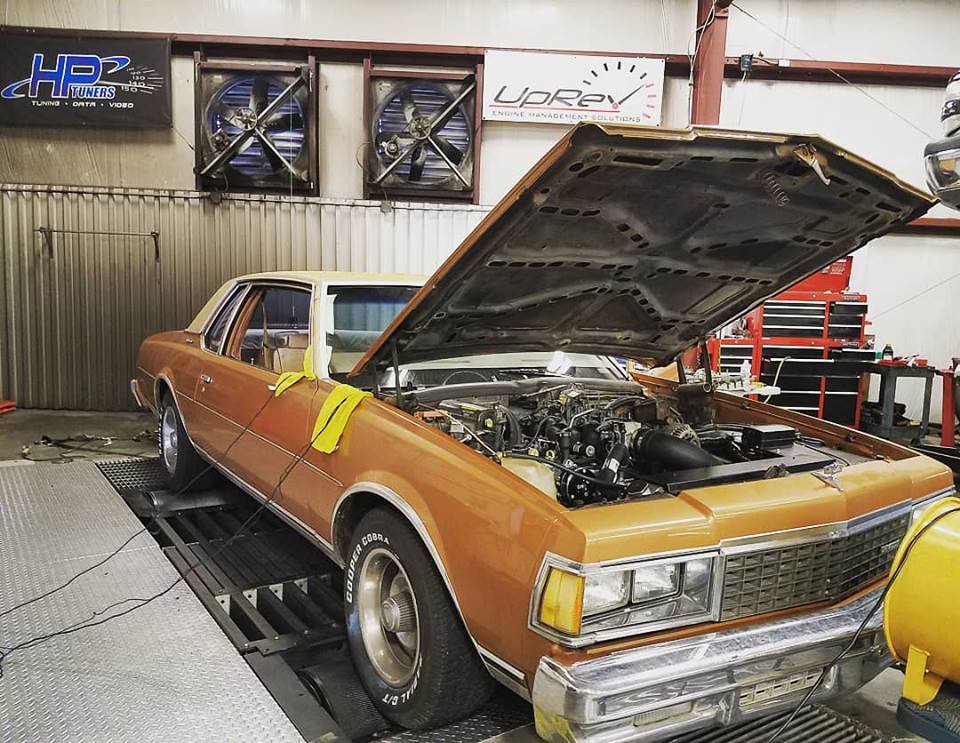

I drove The Caprice to my friend Matt's house so he could take it to his shop to do the final tuning. This was about 18 miles away and was the first time I'd driven the car on an interstate type road. It turned 1450 rpm at 70 miles per hour. I found it hard to keep at 65 mph. You're barely touching the gas even at those speeds and it kept wanting to creep up to 75 and 85 mph without me realizing it. I understand now why the transmission shop believed the torque converter was not locking up. The gearing is so high that it doesn't even lock up until you get closer to 60 or 65 miles per hour. I was releaved to find out it not only engages, but disengages when you apply the brake pedal. There's zero driveline vibration and the tires are balanced well, so though I'm not happy with the BRP kit I will say that they did seem to get the driveline angles correct as the kit advertises. Everything is very smooth. After the tuning the throttle response is much better and the electric fans are working correctly with both fans running on high and low speed with no clicking coming from the relays. Here's where the car spent the week.

Matt had to drive 35-40 miles each way to get to the shop. He got a pretty good picture of the new gauges. I still haven't had time to get into the fuel gauge issue yet.

He put the car on the dyno to tune it for wide open throttle.

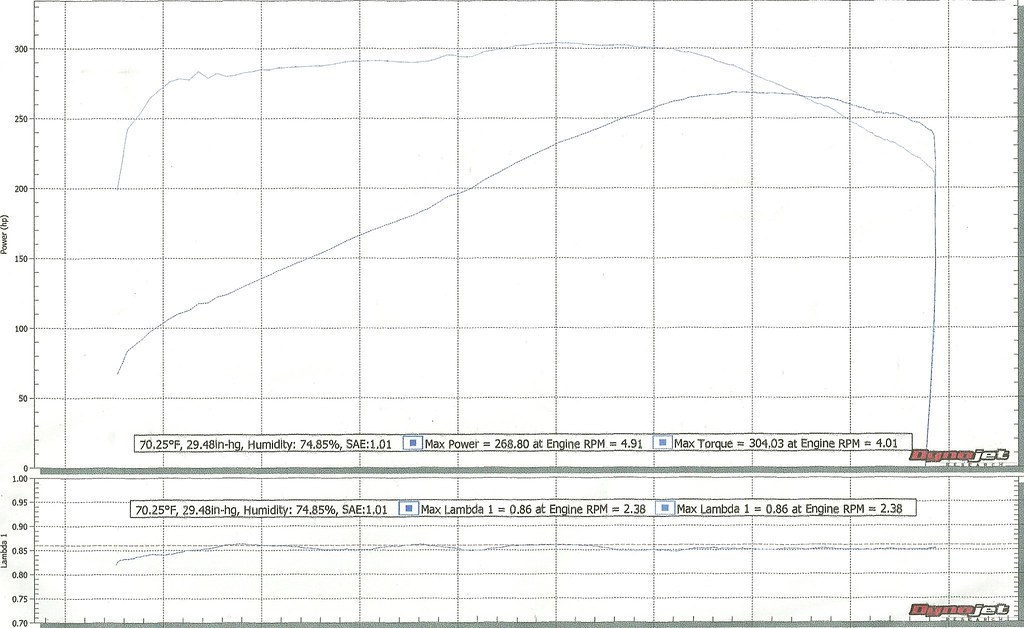

It ended up making 269 horsepower and 304 foot pounds of torque at the wheel with 2:41 gears. That's plenty enough for what I am wanting to do. I will eventually swap out the 2:41 for something closer to a 3:42 with a limited slip.

Matt made a couple trips to the shop in The Caprice. Once, the throttle shut off and threw code P2125, but when the key was turned off it started back and ran fine. Really bad weather and storms all week prevented him from driving it into work a couple days. On the 2nd day home from the shop the throttle began turning off every few minutes, getting more and more frequent. I thought I was going to have to go haul the car home, but the problem ended up being the cruise control wires. I forgot to put black tape over the ends when I zip tied them out of the way and Matt had moved some wires under the dash causing the cruise control wires to short out against the steering column. Tidying up the cruise wires solved the issue. It also developed a small transmission leak at the line on the radiator. I tightened that up and it seemed to have stopped the leak. Also, the dead parking light bulb came back. After looking into that issue it seems I have a short in the parking light wiring just as it comes out of the bulb socket. I'll have to see where the break is and fix it. Matt took it through emissions and it passed with no problem.

Getting back to the gas tank filler neck problem from last weekend; After a lot of effort I realized that even if I could get the bolt out there would be no way to get a nut on the back of it to tighten so I would going to have to take the bumper apart. Even if I could have gotten a bolt and nut back in I was hesitant to grind the head off of that bolt with the gas tank so close. That meant I had to take the bumper off. It was easiest to take the bumper shocks out of the frame to remove the bumper. The bumper shocks mount to the back of the frame, but also have a 10mm bolt that goes into the bottom of the frame facing up. Both of these bolts twisted off on each side which left a stud sticking down, which made pulling the shocks out of the back of the frame very, very difficult. I eventually got them out with various sized prybars, pushbars, screwdrivers and anything I could find to leverage against. I was just about to tie the bumper to a come-along when it finally gave up and decided to let go of the frame.

Here is a better shot of the afflicted area. The bolt on the right came out fine. The hole under the bolt on the left is the access hole I drilled. It ended up being drilled for nothing. The reason it is offset is because there is bracing in the way and that was as close as I could get.

I knew if the clip on the back of that bolt broke then many of the clips for the other bolts would break. There are 19 bolts holding the bumper to the inner structure and 9 came out without breaking the clip. I had to drill the heads off of the rest. This job took all day long and I still didn't get completely finished.

Whoever designed this bumper certainly wasn't on the varsity team. I've taken apart bumpers from quite a few 50's, 60's and 70's cars and I have to say this is the worst design I have seen. The location and design of the braces and clips definitely make things much more difficult than they needed to be.

This particular bumper has the stock mud, mice nest and feces and rocks feature. This bumper came from a parts car I had stored in a barn. I installed it on The Caprice after April totaled it several years ago. The mice in the barn had made a terrible mess and I'm not entirely sure they didn't use this as their official burial grounds at some point.

After a good cleaning with a brush I literally hung the inner structure out to dry.

I got all new clips and bolts. $50 dollars worth. As if this entire process wasn't frustrating enough, I got hit with a big bill on top of it. I'm sure many would say this wasn't necessary, but this is how I wanted the project to be done. The filler neck mount I'm making is the cleanest design without cutting or welding onto the body and this is what was necessary to make that work the way I wanted it.